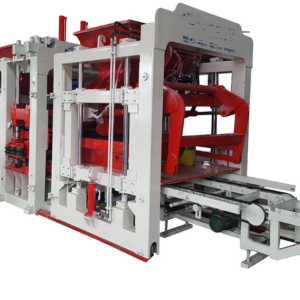

Machine to Make Concrete Blocks

Leading Manufacturer Of Fly Ash Bricks Making Machines, Concrete Brick, Block Making Machines, Paver Block Making Machine, Material Handling.

REIT had exported the fully automatic machine to developed countries including USA, CANADA, SOUTH KOREA and Russia by 2006.

Showing 1–12 of 74 results

-

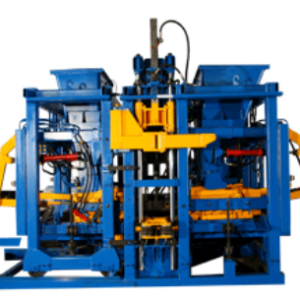

automatic block making machine factories

-

Automatic Block Making Machine Wholesalers

-

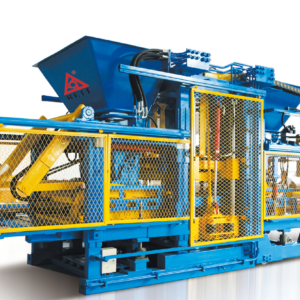

automatic paver block making machine

-

Automatic Paver Block Making Machine

-

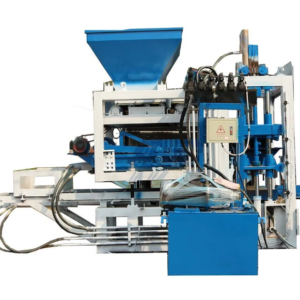

baking free block making machine

-

best quality block making machine

-

Block Making Machine Factory

-

block making machine sale

-

brick and block making machine

-

brick block making machine quotes

-

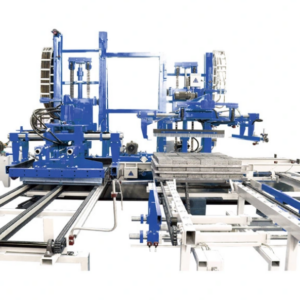

building block making machine

-

Building Block Making Machine

Technical Comparison

| Technical Specification | RTQT12 (High Efficiency) | RT15A (Premium Heavy-Duty) |

| Market Positioning | High ROI for Standard Large-Scale Projects | Supreme Performance for Heavy Infrastructure |

| Cycle Time | 15 – 20 Seconds | 13 – 18 Seconds |

| Pallet Size | 1400 × 1100 mm | 1400 × 1300 mm |

| Vibration Force | 100 – 120 kN | 120 – 150 kN |

| Total Power | 52.5 kW | 65 kW |

| Control System | Siemens PLC Integrated | Advanced Siemens Series with Cloud Diagnostics |

| Best For | Standard Bricks, Pavers, Hollow Blocks | High-Density Curbstones & Large Format Pavers |

Find Your Industry Solution

Urban Infrastructure & Public Works

-

Focus: Extreme durability, precision dimensions, and high-load capacity.

-

Target Products: Curbstones, heavy-duty drainage blocks, and municipal road pavers.

-

Recommended Model: RT15A — Designed with high-intensity vibration to ensure the density and frost resistance required for government projects.

-

Key Benefit: Meet strict international standards for compressive strength and wear resistance.

Affordable Housing & Construction

-

Focus: High-volume output, low cost-per-unit, and raw material versatility.

-

Target Products: Load-bearing hollow blocks, standard solid bricks, and lightweight wall blocks.

-

Recommended Model: RTQT10 / RT9DA — Built for 24/7 reliability to supply massive housing developments rapidly.

-

Key Benefit: Optimized for using local waste materials (fly ash, slag) to reduce production costs.

Commercial Landscaping & Decorative Projects

-

Focus: Aesthetic flexibility, vibrant coloring, and complex textures.

-

Target Products: Interlocking pavers, colored architectural bricks, and grass-hole pavers for parking.

-

Recommended Model: RTQT12 (with Face Mix System) — Features a secondary feeding system for precise color surface application.

-

Key Benefit: Produce high-margin “premium” stones that command a higher market price for urban beautification.