ทำไมคุณถึงเป็น เครื่องทำคอนกรีตบล็อก การผลิตบล็อกที่มีข้อบกพร่อง? หากเครื่องทำบล็อกคอนกรีตอัตโนมัติของคุณผลิตบล็อกที่มีข้อบกพร่อง, คุณไม่ได้อยู่คนเดียว. ปัญหาทั่วไปเช่นรอยแตก, รูปร่างไม่สม่ำเสมอ, หรือบล็อกที่อ่อนแออาจเกิดจากหลายปัจจัย.

พร้อมปรับปรุงคุณภาพบล็อกของคุณ? ต่อไปนี้คือรายละเอียดสาเหตุและวิธีแก้ไข.

1. อัตราส่วนผสมที่ไม่เหมาะสม:

สาเหตุที่พบบ่อยที่สุดสำหรับบล็อกที่มีข้อบกพร่องคืออัตราส่วนการผสมที่ไม่ถูกต้อง. ถ้าเป็นปูนซีเมนต์, ทราย, และมวลรวมไม่ได้สัดส่วนอย่างถูกต้อง, บล็อกอาจอ่อนแอหรือไม่สม่ำเสมอ. ปฏิบัติตามอัตราส่วนการผสมที่แนะนำเสมอ และให้แน่ใจว่าการผสมสม่ำเสมอ.

2. กระบวนการบ่มไม่เพียงพอ:

การบ่มที่เหมาะสมเป็นสิ่งสำคัญสำหรับความแข็งแรงของบล็อก. เวลาในการบ่มไม่เพียงพอหรือวิธีการบ่มที่ไม่ดีอาจส่งผลให้บล็อกเปราะหรือแตกร้าว. ตรวจสอบให้แน่ใจว่าอิฐถูกเก็บไว้ในสภาพแวดล้อมที่มีการควบคุมและมีความชื้นเพียงพอตามระยะเวลาการบ่มที่แนะนำ.

3. วัตถุดิบคุณภาพต่ำ:

วัตถุดิบคุณภาพต่ำนำไปสู่บล็อกที่ไม่ได้มาตรฐาน. การใช้ปูนซีเมนต์คุณภาพต่ำ, ทรายที่ปนเปื้อน, หรือการรวมคะแนนที่ไม่ดีอาจส่งผลต่อความสมบูรณ์ของบล็อกของคุณได้. จัดหาวัตถุดิบคุณภาพสูงและตรวจสอบก่อนใช้งานเสมอ.

4. ปัญหาการสอบเทียบเครื่อง:

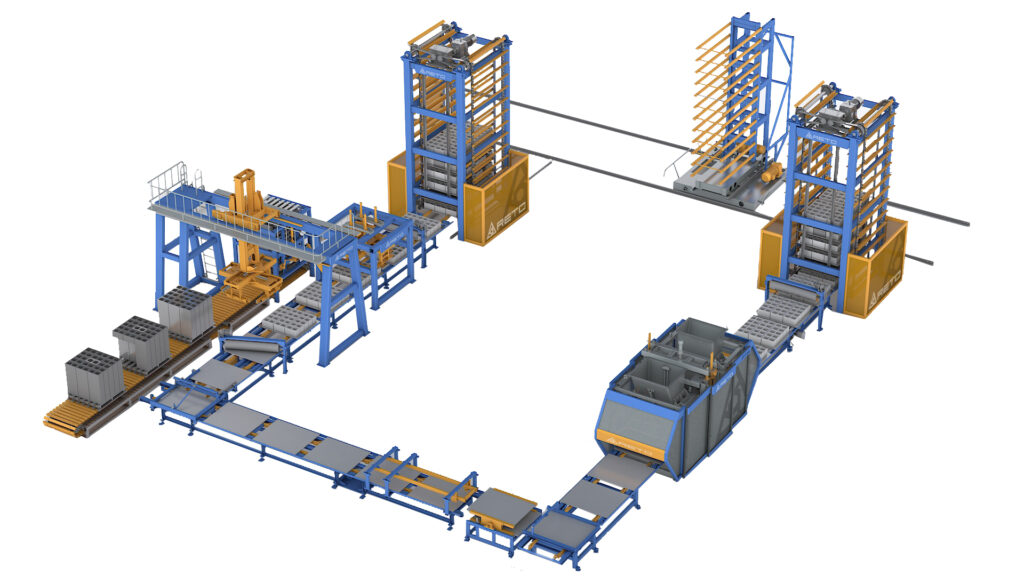

หากเครื่องอิฐซีเมนต์ของคุณโดย โรงงานผลิตเครื่องจักรผลิตบล็อกคอนกรีต ไม่ได้ปรับเทียบอย่างถูกต้อง, กระบวนการขึ้นรูปอาจไม่ทำงานตามที่ตั้งใจไว้, ส่งผลให้บล็อกไม่เรียบหรือชำรุด. ตรวจสอบและปรับการตั้งค่าของเครื่องอย่างสม่ำเสมอ, รวมถึงแรงดันและความถี่การสั่นสะเทือน, เพื่อให้แน่ใจว่าการผลิตมีความสม่ำเสมอ.

5. การบดอัดไม่เพียงพอ:

อิฐที่อัดแน่นไม่ถูกต้องมักจะมีช่องอากาศ, ส่งผลให้โครงสร้างอ่อนแอและเป็นรูพรุน. ตรวจสอบให้แน่ใจว่าเครื่องจักรของคุณใช้แรงกดและการสั่นสะเทือนในปริมาณที่เหมาะสมในระหว่างกระบวนการขึ้นรูป.

6. ข้อผิดพลาดของตัวดำเนินการ:

บางครั้ง, ปัญหาอยู่ที่ข้อผิดพลาดในการดำเนินงาน. ผู้ปฏิบัติงานที่ไม่ได้รับการฝึกอบรมอาจใช้งานเครื่องจักรในทางที่ผิดหรือมองข้ามขั้นตอนสำคัญ. ตรวจสอบให้แน่ใจว่าทีมของคุณได้รับการฝึกอบรมมาอย่างดีและปฏิบัติตามขั้นตอนที่ถูกต้อง.

โดยการระบุปัญหาเหล่านี้และใช้แนวทางแก้ไขที่เหมาะสม, คุณสามารถปรับปรุงคุณภาพของบล็อกคอนกรีตของคุณและรับประกันความสม่ำเสมอ, การผลิตที่ปราศจากข้อบกพร่อง. ต้องการคำแนะนำจากผู้เชี่ยวชาญเพิ่มเติมเกี่ยวกับการเพิ่มประสิทธิภาพการผลิตของคุณ? คลิกที่นี่เพื่อดูข้อมูลเพิ่มเติม: https://wa.me/+8613811437192.