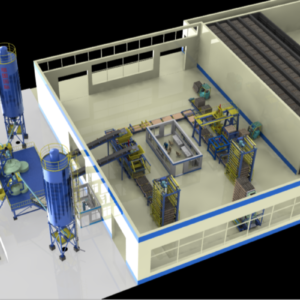

Semi Automatic Block Making Machine TECHNICAL SPECIFACTION

1) STATIONARY BLOCK MACHINE REIT- RT6C RT6

CAPACITY/PER PALLET : – 6 HOLLOW BLOCKS 400×200×200MM

PALLET SIZE : – 900×700×25MM PVC

WORK AREA : – 820×650MM

PRODUCT HEIGHT : – 50-220MM

OPERATION CYCLE : – 15~30S

VIBRATION MOTOR : – 2×7.5KW

OSCILLATION FORCE : – 100 kN

MACHINE WEIGHT : – ABOUT 7 TON

The block machine can be universally used for the manufacturing of pavers with and without face mix, kerb stones, hollow blocks and similar elements.

BODY

The machine is built of strong section steel with 2 guiding columns with which the mould moves up and down. The seat of mould is equipped with synchronized connecting rod so that both sides of two end of mould is up and down synchronously. The mould and mould head linked with their seat through the special rubber bush.

FILLER SYSTEM

The filler system is integrated one which can be moved out or into body when need. The filler box and hopper is fixed on the support frame. Their height is adjustable according to the product height. The capacity of base concrete hopper is approx 0.5 m3 and outlet is driven by hydraulic cylinder.

The filler box is driven by hydraulic cylinder and the guiding rollers are inside of U rail. In the filler box there are rotating bars with sticks driven by a german made hydraulic motor , which with concrete compulsory movements can make the filling process fast and wet concrete in the mould well-distributed. As the final result the products are high quality.

COMPACTING SYSTEM

The system consists of two twin-shaft heavy-duty special synchronous vibrators fixed on vibrating table, the vibrator having 2 synchronized unbalances and generating vertical oscillations. Due to this force the vibrating table, the pallet and the mould filled with concrete, move up and down.

The concrete in the mould is compacted. The vibrator is Patent product which equipped the electronic brake system (also Patent). The vibrating frequency and amplitude is adjusted according to the products and material. There are many shock absorbing pads between vibrating table and body.

VIBRATOR MOTOR MAKE : – ABB

POWER : – 7.5 KW

QTY OF MOTOR : – 2 Nos.

HYDRAULIC STATION

The hydraulic station consisting of 850 litres oil tank, oil pump, electric motor and cooling system is integrated together with the valve station beside of the block machine, which is separated with block machine and linked with soft heavy duty hydraulic pipes.The oil pump, valves, cylinders and element are Italian and German products such as ATOS, REXROTH , PARKER.MOTOR MAKE: – ABB

COOLING TOWER CAPACITY: – 65 TR (BUYER SCOPE)

1.1) GREEN BLOCK CONVEYOR

As transport equipment on manufacturing wet side, green block conveyor is designed for smooth transportation, driven by frequency controlled motor. At the end there is nylon rollers and special brake device.

DRIVEN MOTOR: 1.5KW

TRANSPORT SPEED: 0.1—0.6M/S

GEARED MOTOR MAKE: – SEW

1.2) MOBILE STACKING DEVICE

According to the program this device transfer the pallets with wet products and stack them automatically, two pallets once.It is the bridge frame structure. Under the both supports there are two sets of driving and driven wheels. There are two sets of holders at both side of frame which holds pallets with wet products. It is controlled by PLC.

MOBILE DRIVE MOTOR: 1.5KW

ELEVATING MOTOR: 2.2KW

GEARED MOTOR MAKE: – SEW

PALLET HOPPER

The Pallet hopper is designed to store 6 pallets.

2) BATCHING SYSTEM FOR BASE

2.1 BATCHING MACHINE FOR BASE: 3*6M3

Total three storage hoppers of capacity 6 CUM each, with one vibrator in each bin, Heavy duty structure and weighing belt conveyor of 0.5 CUM batch capacity. Driven Motor: – 5.5 Kw

LOAD CELL: – MAKE – ADI

BELT WIDTH: – 600MM

VIBRATOR MAKE: – COSBEN

2.2 DRY MIX CONVEYOR

With Dry mix belt conveyor of Chevron type for discharging raw material from batching plant to mixer.

DRIVEN MOTOR: 2.2KW

BELT TYPE: – CHEVRON

2.3 CEMENT SCALE:

Weighing Hopper with digital based load cell, The Amplifier, pneumatic butter fly valve are Included.

WEIGHING CAPACITY: 500KG

LOAD CELL: – MAKE – ADI

VIBRATOR MAKE: – COSBEN

2.3.1 ONE SET OF CEMENTS SCREWS

Technical Data:

Diameter: 168mm, Conveying Length Approx.: 7000mm, Driven Motor: 5.5kw, Capacity: 20ton/Hr.

MAKE: – COSBEN

2.4 PNEUMATIC GROUPS

The pneumatic group is the acting device of related equipment with mixing plant, block machine and pallet feeder. The group includes compressor, pipe or hose, filter, cylinders, valves and so on.

AIR COMPRESSOR MAKE: – ANEST IWATA

POWER: – 2.2KW

3 MIXING PLANT

3.1 MAKE: – SICOMA, PLANETARY MIXER MP 750/500,

DRY FILLING CAPACITY 750 lt, COMPACTED CONCRETE OUTPUT 500 lt,

WITH ONE MIXING STAR EQUIPPED WITH THREE ARMS, WITH TWO SCAPER ARMS

WITH THE FOLLOWING CHARACTERISTICS AND ACCESSORIES:Cabling and Wiring of Motors and Auxiliary Devices (Limit Switches and Solenoid Valves) to a IP55 Junction Box installed on the Mixer (OPTIONAL) ,1 Mixing Motor 18,5 kw, Hydraulic Power Pack with 1,5 kw Motor, Manual Pump for the Emergency Opening (OPTIONAL), Liner Plates combination of Hi-Chrome casting and wear resistant plate. Mixing and Scraping Blades in Ni-Hard Cast Iron 600HB. Covers with inspection hatch and half-moon door protected by Limit Switch Compliant with the CE regulations. Hydraulically operated Discharge Door, with two limit switches. The Mixer can be equipped with Maximum 4 Discharge Doors with additional Cost.

3.2 WET MIX CONVEYOR

Flat belt conveyor for transferring the ready mix material to block machine feeding hopper.

DRIVEN MOTOR: 5.5 KW

3.3 MOISTURE PROBE

“HYDRONIX – U. K.” MAKE MOISTURE TRANSMITTER

Model: “HYDRO MIX – VIII”, Construction: Body: Stainless Steel

Faceplate: Ceramic, Protection Ring: Hardened Steel

Analogue Output: 4-20 mA DC, Power Supply: +15 VDC +30 VDC

4) BATCHING SYSTEM FOR FACE (OPTIONAL)

4.1 BATCHING MACHINE FOR BASE: 1*6M3

Single bin storage hoppers of capacity 6 CUM each, with one vibrator in, Heavy duty structure and weighing belt conveyor of 0.5 CUM batch capacity.

DRIVEN MOTOR: – 1.5KW

LOAD CELL: – MAKE – ADI

BELT WIDTH: – 600MM

VIBRATOR MAKE: – COSBEN

4.2 DRY MIX CONVEYOR

With Dry mix belt conveyor of Chevron type for discharging raw material from batching plant to mixer.

DRIVEN MOTOR: 1.5KW

BELT TYPE: – CHEVRON

4.3 CEMENT SCALE:

Weighing Hopper with digital based load cell, The Amplifier, pneumatic butter fly valve are Included.

WEIGHING CAPACITY: 150KG

LOAD CELL: – MAKE – ADI

VIBRATOR MAKE: – COSBEN

4.4 WATER WEIGH BATCHING SYSTEM

LOAD CELL BASED DOSING SYSTEM

5 MIXING PLANT (OPTIONAL)

5.1 MAKE: – SICOMA, PLANETARY MIXER MPC 375/250,

PLANETARY MIXER MP375/250, DRY FILLING CAPACITY 375 lt,COMPACTED CONCRETE OUTPUT 250 lt, WITH ONE MIXING STAR EQUIPPED WITH THREE ARMSWITH ONE SCAPER ARM, WITH THE FOLLOWING CHARACTERISTICS AND ACCESSORIES:

Cabling and Wiring of Motors and Auxiliary Devices (Limit Switches and Solenoid Valves) to a IP55 Junction Box installed on the Mixer (OPTIONAL) 1 Mixing Motor 7,5 kW Hydraulic Power Pack with 1,5 kW Motor, Manual Pump for the Emergency Opening (OPTIONAL)Liner Plates in Weld Clad Hi-chrome Steel , 10 mm Thickness Mixing and Scraping Blades in Ni-Hard Cast Iron 600HB Covers with inspection hatch and half moon door protected by Limit Switch, compliant with the CE regulations.1 Hydraulically operated Discharge Door, with two limit switches.

5.2WET MIX CONVEYOR

Flat belt conveyor for transferring the ready mix material to block machine feeding hopper.

DRIVEN MOTOR: 3.7 KW

TOOL KIT MOULD

Set of all type of spanners for daily maintenance activity

ELECTRIC CONTROL GROUP

Electric control for block machine

The control system controls whole production line. The system consists of power panel, control desk. The Siemens PLC and the power unit is housed in a control desk which includes joy-sticks for manual machine operation and an integrated Siemens display for data in- and output. The system stores the data for deferent products.

The elements are famous international brand products such as Siemens, Omron, and Toshiba and so on.

CONTROL FOR BASE CONCRETE MIXING AND BATCHING

Automatically control base concrete batching and weighing, water metering and moisture measuring, mixing and transporting to block machine. It can input the related parameter to the control unit according to the production frequency of block machine, the batching and mixing system can feed, mix, water meter, moisture measure, and transport the aggregate to the hoppers of block machine. The transport is controlled automatically and manually as well. The statistic and store of data can realized by the computer, it can memorize much formula.

CONTROL FOR FACE CONCRETE MIXING AND BATCHING (OPTIONAL)

Automatically control face concrete batching and weighing, water metering and moisture measuring, mixing and transporting to block machine. It can input the related parameter to the control unit according to the production frequency of block machine, the batching and mixing system can feed, mix, water meter, moisture measure, and transport the aggregate to the hoppers of block machine. The transport is controlled automatically and manually as well. The statistic and store of data can realized by the computer, it can memorize much formula.

FEW COUSTMERS IN INDIA

PRODUCTS MADE BY REIT MACHINE

Additional information

| Cycle Time | 15S-25S (depend on the products) |

|---|---|

| Pallet size | 1350×700 mm |

| Machine Weight | app 10 ton |

| Product height | 50~300mm |