Block Making Machine Factory

| Product Name | block making machine |

| Vibration Force | 80KN |

| Vibration Power | 2X2.5KW |

| Driven Motor | 1.5kw |

| Operation Cycle | 15~30s |

| Transport Speed | 0.1—0.8m/s |

We encourage you to connect with REIT for detailed block making machine data information and to request information on wholesale prices.

What is block making machine:

block making machine represents specialized equipment used for manufacturing concrete building blocks, paving units, and various precast concrete items. This advanced machinery optimizes the processes of mixing, shaping, and curing concrete, resulting in a robust, efficient, and high-quality production that outperforms traditional manual techniques. As a leading block making machine factory, REIT is at the forefront of construction industry innovation. Their exceptional and groundbreaking equipment is reshaping the foundations of building methodologies in China and globally, paving the way for superior and sustainable construction practices.

How Do block making machine Work?

- Raw material loading: With block making machine, the first step is to load the machine with the necessary ingredients such as cement, sand, gravel, and water. This can be done manually or through an automated feeding system.

- Mixing: Once the raw materials are loaded, block making machine ensures thorough mixing by using a high-speed and high-intensity mixer. This process ensures that the concrete blend is consistent and well-combined.

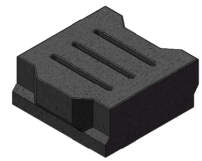

- Molding: After the mixing is complete, the concrete mixture is poured into molds of various sizes and shapes. block making machine then applies compaction and vibration techniques to remove air pockets and achieve a uniform and solid structure.

- Ejection: Once the blocks have been formed, block making machine efficiently ejects them from the molds. This step is crucial in preparing the blocks for the next stage of the production process.

- Curing: The ejected blocks are then moved to a designated curing area where they are allowed to cure and harden over a specific period of time, typically 24-48 hours. This curing process ensures the blocks achieve optimal strength and durability.

The Diverse Applications of block making machine

- Residential construction: block making machine serve as a cornerstone in residential construction, offering a reliable supply of concrete blocks for building strong foundations, robust walls, and other essential components in homes and residential structures.

- Commercial construction: The versatility of block making machine extends to commercial construction, providing high-quality concrete blocks for the construction of office buildings, shopping centers, warehouses, and various other commercial properties.

- Infrastructure projects: block making machine play a vital role in infrastructure development, supplying durable concrete blocks for the construction of bridges, highways, dams, and other significant infrastructure projects, ensuring stability and longevity.

- Landscaping: Enhancing outdoor spaces, block making machine produce concrete pavers and retaining wall blocks that find wide application in landscaping projects. They contribute to the creation of visually appealing driveways, patios, and retaining walls, blending functionality and aesthetics seamlessly.

WorkShop Show

FAQ:

How Much Do Your Block Making Machine Plants Cost?

Concrete blocks making machine plants can be divided into fully automatic, automatic and semi-automatic categories. According to the degree of automation and daily output needed, the prices can vary. You can email us for a price based on your specific needs. We will put together options within your budget.

- Fully Automated Block Machine Plant systems range from US $550,000 to nearly US$1,500,000

- Automatic Block Machine Plant systems range from US $150,000 to US $450,000

- Semi-Automated Block Machine Plant systems range from US $15,000 – US $60,000.

Can Your Machines Make Other Products In Addition To Concrete Blocks And Paving Stones?

- Absolutely, with a simple mold change our machines can make a wide variety of products. Some models of machines are best suited and more profitable for you to produce certain products on than others.

- Our machines have manufactured a wide variety of concre products. I’ve listed below, a few of the hundreds of products that have been produced on our equipment.

- Concrete hollow core building blocks, Solid Building blocks, Interlocking street pavers, Concrete Erosion Control blocks, Solid and cored bricks, Insolated building blocks, Mortarless building blocks, Retaining Wall blocks.

Do You Sell Equipment Internationally?

Absolutely. We have shipped equipment all around the world.we supplied in USA,Canada,Russia, Korea, Malaysia, India, Middle east North Africa, Iran, China also . In all total, We’ve supplied concrete machinery equipment in over 100 countries and area.