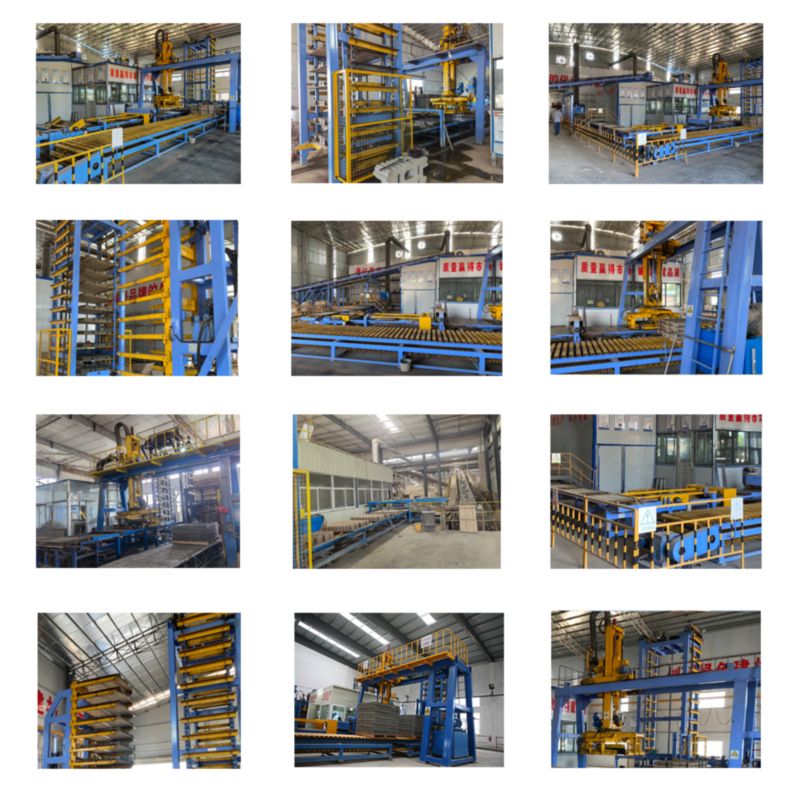

Fully automatic block base concrete feeding device and face concrete feeding device can be moved independently, in order to adjust and fix machines easier. It can be universally used for the manufacturing of pavers with and without face mix, kerbstones, hollow blocks and similar elements.Fully Automatic Production Line for making Block,Brick,Interlock Paver and Curb Stone.Multiple systems cooperate to complete production.

Introduce

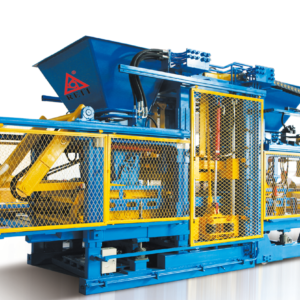

1、Machine body

The machine is built of strong hollow and rectangle steel which is welded in fatigue resistance process. The closed frame structure is very strong and rigid. 4 chrome plate guiding columns are fixed on the body of machine for guiding the up mould and down mould. Driving by hydraulic cylinders, the moulds move up and down exactly and rapidly along the guiding columns, moreover without impacting at the end. Using extended length of sleeves for the coincidence of mould and guiding columns ensure the guiding precision and prolong its using period.

2、Filler Box

The filler box is a unit which can be take out and in conveniently from the machine (Base or face feeding device), it is easy for examining, repairing, and maintaining. Both concrete storage hopper and filler box are fixed on the frame, and move synchronously when the height of products is changed. The capacity of concrete storage hopper is app 1500L, and its outlet is driven by hydraulic cylinder. The hour, times and degree for open and close the outlet can be adjusted by control system. There is level indicator in the hopper, which can give signals for filling or stopping the concrete. The filler box is supported by the guiding wheels in the U guiding slot of block machine. The filler box is driven by two synchronized hydraulic cylinders through the arms of both sides and its movement is controlled by a limited switch moreover can change according to the raw material and frame of products. There is a special shaking grid driven by a hydraulic motor in the filler box, which with compulsory movements can make the filling process fast and wet concrete in the mould well-distributed.

3、The Compacting System

Under the vibrating table and on the up mould socket the vibrators are fixed, so forms “Down mould vibrating plus up mould vibrating plus up mould pressing” as the compacting system. The formation and compacting process includes pre-vibrating and main vibrating. 4 groups of twin-shaft heavy-duty special synchronous vibrators for which REIT has the patent are fixed under vibrating table and driven by 4 SERVO motors. The special synchronous device ensures that the four vibrators work uprightly at the same time and generate vertical oscillations. The amplitude and frequency of vibrators can be adjusted according to the different raw material and blocks so as to make all of the raw material reach ideal level of the dense blocks. The vibrating system and body are separated by a high effect absorbing-vibrating system, so the vibrating energy which is transferred to the foundation and frame of machine are small, so it can make building foundation and installing become very easy.

4、Pallet Supply Device

Combining by stationary bucket and moveable frame, the pallet supply device can transfer the empty pallet to the vibrating table of block machine automatically and carry the green blocks to the green block conveyor. The moveable frame is driven by the hydraulic cylinder and move forward and back through adjust-speed device.

5、Face Concrete Device (2nd feeding device) (Optional)

It is for the manufacturing of products with face concrete. Its frame is welded by strong rectangle steel. It is in front of the block machine. On the base of special frame and trail it can be linked and separated with the block machine manually easily when cleaning and mould exchanging. Concrete storage hopper is 800L and its gate is operated by hydraulic cylinder. There is a level indicator in the hopper. The filler box is driven by two synchronized hydraulic cylinders through the arms of both sides and its movement is controlled by a limited switch. The height of feed table with feed box is adjustable.

6、Hydraulic Drive Unit

The hydraulic drive unit which are made by world-famous hydraulic elements such as Uranus and Japanese Yuken brand etc. supplies the power for equipment. All of the hydraulic elements are integrated in the form of hydraulic unit. The hydraulic unit are independent from block machine as the station which is equipped with radiator and filter for recycle oil so as to prolong working period of hydraulic unit and stability of operation. It is linked with block machine by the soft heavy-duty hydraulic hose. The joints of pipe are centralized arrangement. All of the hydraulic pipes are put on the block machine with hard pipe except the soft ones for connecting with cylinder. The buffer unit is equipped inside the cylinders, the dimensions of pipeline are enough and balance loop is adopted as to ensure the steady, rapid and smooth operation of equipment.

7、Auto Control System

It is one sub-system of intelligent control and management system including power panel, control desk, monitor display and PC computer, the PLC control system has friend interface, data input and output, diagram display from which the operator can operate the equipment easily and get the operative information of equipment. The system can record production data and operation data which can be used and revised easily to reduce the adjustment time for new products. The English version of operation system is supplied. The English version of operation system is supplied.

The PLC itself is a Siemens product. Other elements are from famous international company such as Omron, ABB.

8、Automatic Foam Plate Device(Optional)

In the production process, the foam plate is inserted into the moulds automatically before the filling process. Then the filling process begins to operate and blocks are finally made. This device is specially designed for producing the insulation concrete blocks. It’s optional according to customers’ special requirement.