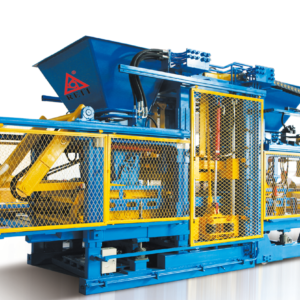

Full automatic block machine can produce all kinds of concrete building blocks, such as hollow brick, solid brick, bricklaying and facing brick.

Various paving bricks, such as chain brick, square slab and curb brick; Slope protection and dam building blocks used in water conservancy industry.

And various special concrete components for parks, airports,docks and other purposes. In addition to ordinary concrete as raw materials, various wastes such as fly ash, coal gangue, slag and treated solid waste can also be used as raw materials.

The full-automatic block machine is suitable for manufacturing high-quality concrete blocks and can meet the requirements of users for all high-quality concrete processing.

The equipment can use fly ash, slag or other industrial waste residue, sand, stone and cement to produce various concrete building blocks such as blocks, color floor tiles and curb stones by changing molds.

Main structure and technical features:

- super strong section steel and international advanced welding technology are adopted to make the body firm and durable.

- composite motion rapid distribution system (ruitu patent), with fast and uniform material filling mold and short forming cycle, is especially suitable for the production of light aggregate such as fly ash.

- ensure that the double shaft high-efficiency vibration system (ruitu patent), the amplitude and exciting force can be adjusted steplessly, so that the products can achieve the best compactness and improve the strength.

- high efficiency vibration isolation system, the vibration force transmitted to the frame and foundation is very small, which is very convenient to use and install.

- change the mold at will, select the secondary distribution device, produce products with surface layer, produce multiple varieties and use one machine for multiple purposes.

- the hydraulic system adopts hydraulic components imported from Taiwan and Japan, integrated hydraulic station and automatic oil temperature adjustment to ensure the continuous operation of the equipment for a long time.

- The control system adopts the international brand Siemens PLC control, and the electrical components are provided by world-famous companies, with reliable operation. It has three operations: automatic, linkage and manual, and electronically displays the fault point. Convenient maintenance.

- The appearance design is reasonable, the simple workshop can be matched, the investment scale is small, the production organization is flexible, and the products can adapt to a wide range.

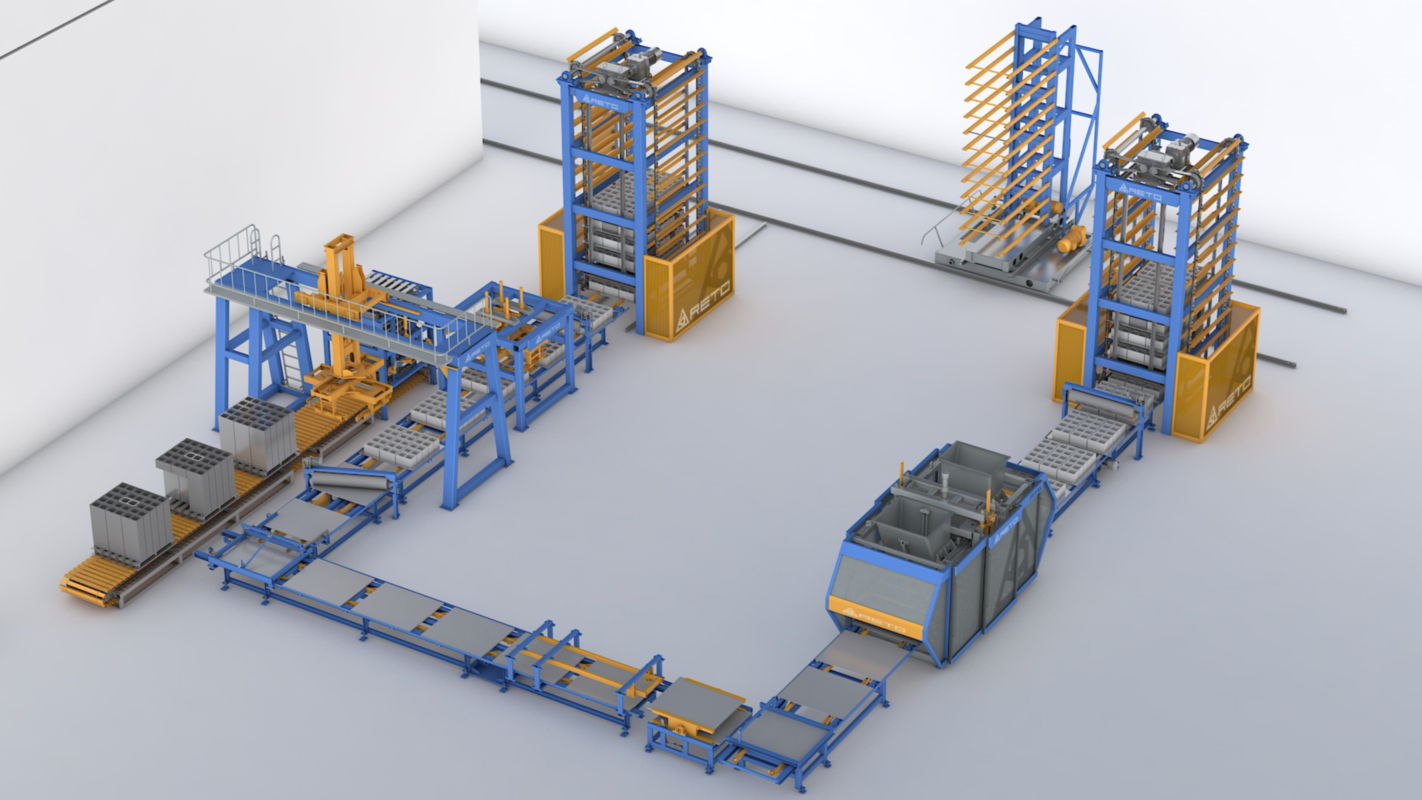

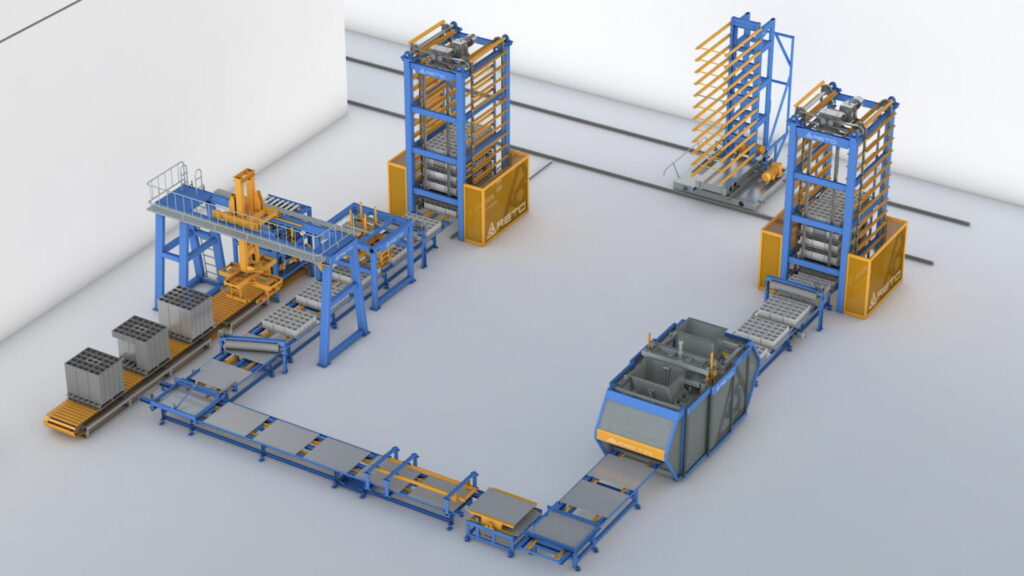

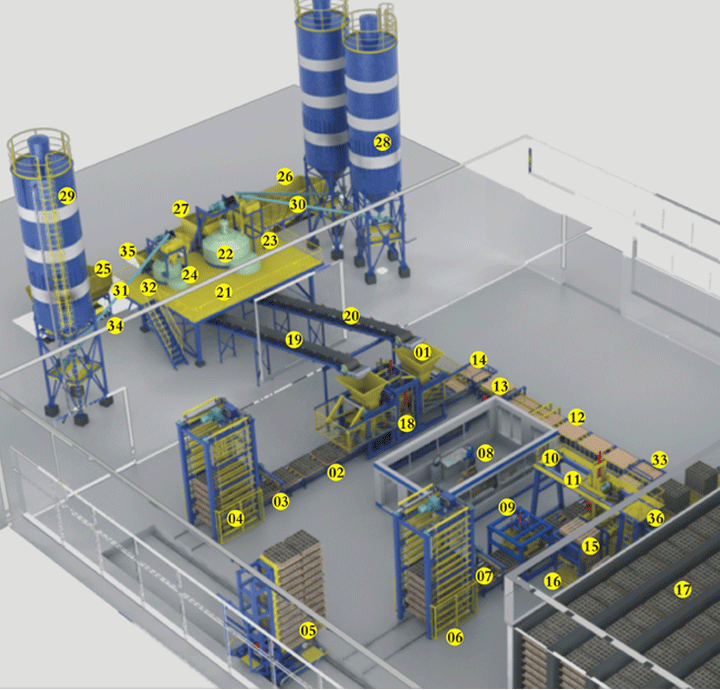

1. Molding host

2. Lifting plate pitch machine

3. Product brush

4. Plate lifter

5. Program controlled letter car

6. Board lowering machine

7. Plate lowering pitch machine

8. Central control room

9. Full code device

10. Stacker

11. Pallet cleaning device

12. Pallet pitch machine

13. Turnover machine

14. Pallet bin

15. Pallet warehouse

16. Finished product conveyor

17. Curing kiln

18. Internal board lowering machine

19. Bottom discharge belt

20. Fabric discharge belt

21. Mixing platform

22. Primer mixer

23. Primer cement scale

24. Fabric mixer

25. Fabric batching station

26. Bottom material batching station

27. Bottom material elevator

28. Cement silo

29. Cement silo

30. Cement screw conveyor

31. Cement screw conveyor

32. Fabric color weighing system

33. Pallet collection bin

34. Fabric cement scale

35. Fabric elevator