★Bancuh konkrit

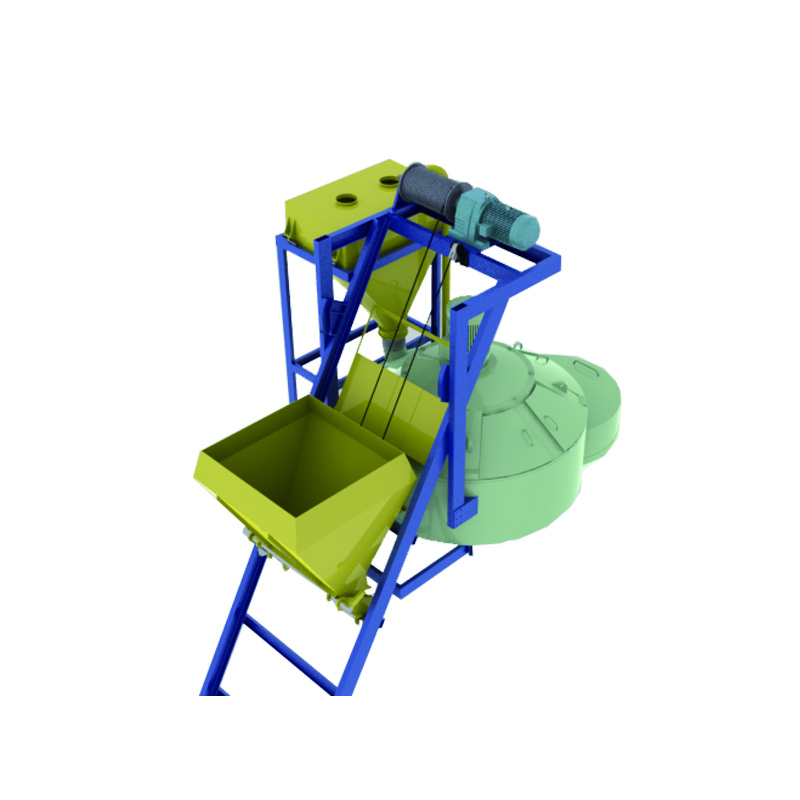

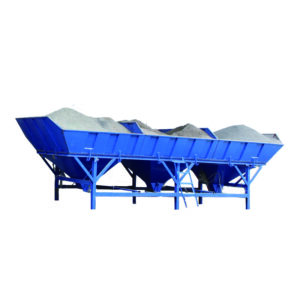

Pembancuh konkrit ialah mesin yang mencampur simen, pasir dan kerikil agregat dan air ke dalam campuran konkrit. Ia terutamanya terdiri daripada drum pencampuran, mekanisme pemakanan dan pelepasan, sistem bekalan air, penggerak utama, mekanisme penghantaran, bingkai dan peranti sokongan. Mengikut sifat bekerja, ia boleh dibahagikan kepada jenis kelompok (jenis batch) dan jenis berterusan; mengikut prinsip kacau, ia boleh dibahagikan kepada jenis jatuh sendiri dan jenis paksa; mengikut kaedah pemasangan, ia boleh dibahagikan kepada jenis tetap dan jenis mudah alih; Mengikut struktur dram pengadun, ia dibahagikan kepada jenis pir, jenis gendang, kon berganda, jenis aci menegak cakera dan jenis aci mendatar alur bulat.

Pengadun konkrit termasuk mekanisme kuasa yang disambungkan dengan mekanisme penghantaran melalui aci dan dram yang digerakkan oleh mekanisme penghantaran. Gear gelang disusun pada badan silinder dram, dan gear disusun pada aci penghantaran untuk menyatu dengan gear gelang. Model utiliti mempunyai struktur yang mudah dan munasabah. Selepas gear dan gear gelang disirat, fenomena gelinciran antara penggelek penyokong dan dram pengadun boleh diatasi dengan berkesan dalam cuaca hujan dan berkabus; mekanisme penghantaran yang diterima pakai boleh memastikan lagi penghapusan jurang antara penggelek sokongan dan dram pengadun. daripada gelinciran.

★Selamat digunakan

1. Pengadun hendaklah ditetapkan dalam kedudukan rata, dan gandar hadapan dan belakang hendaklah berlapik dengan kayu segi empat sama, supaya tayar diletakkan di udara, supaya mengelakkan berjalan apabila bermula.

2. Pengadun harus melaksanakan perlindungan kebocoran sekunder. Selepas bekalan kuasa dihidupkan sebelum pergi bekerja, ia mesti diperiksa dengan teliti, dan ia boleh digunakan hanya selepas pemindahan ujian kereta kosong itu dianggap layak. Semasa operasi percubaan, ia harus diperiksa sama ada kelajuan putaran dram pembancuh adalah sesuai. Secara amnya, kelajuan kereta kosong lebih laju sedikit daripada kereta (selepas memuatkan) dengan 2~3 pusingan. Jika perbezaannya besar, nisbah roda pemanduan kepada roda penghantaran perlu dilaraskan.

3. Arah putaran drum pembancuh hendaklah mengikut arah yang ditunjukkan oleh anak panah. Jika ianya tidak benar, pendawaian motor hendaklah diperbetulkan.

4. Periksa sama ada klac transmisi dan brek adalah fleksibel dan boleh dipercayai, sama ada tali dawai itu rosak, sama ada takal trek dalam keadaan baik, sama ada terdapat halangan di sekeliling dan pelinciran pelbagai bahagian, dan lain-lain.

5. Selepas menghidupkan mesin, sentiasa memberi perhatian sama ada operasi setiap bahagian pengadun adalah normal. Apabila ditutup, sentiasa periksa sama ada bilah pengadun bengkok, dan sama ada skru terjatuh atau longgar.

6. Apabila konkrit selesai bercampur atau ia dijangka berhenti lebih daripada 1 jam, di samping mengeringkan bahan-bahan yang tinggal, tuangkan batu dan air ke dalam dram yang bergoncang, hidupkan mesin, bilas mortar yang melekat pada tong, dan kemudian melepaskan semuanya. Seharusnya tiada air terkumpul di dalam tong untuk mengelakkan tong dan bilah daripada berkarat. Pada masa yang sama, pengumpulan habuk di luar dram pembancuh juga perlu dibersihkan untuk memastikan jentera bersih dan dalam keadaan baik.

7. Selepas keluar kerja dan apabila mesin tidak digunakan, suis hendaklah dimatikan dan kotak suis hendaklah dikunci untuk memastikan keselamatan.