Dalam industri pembinaan yang sentiasa berkembang, kecekapan dan produktiviti adalah diutamakan. Mesin membuat blok penurap konkrit automatik telah muncul sebagai penukar permainan, mengubah pengeluaran penurap konkrit, komponen penting dalam jalan masuk, laluan pejalan kaki, patio, dan permukaan berturap lain. Mesin ini memanfaatkan automasi dan teknologi canggih untuk menyelaraskan proses pembuatan, memastikan kualiti yang konsisten, keperluan buruh dikurangkan, dan peningkatan kapasiti pengeluaran. Catatan blog yang komprehensif ini menyelidiki dunia automatik blok konkrit makialah mesin, meneroka jenis mereka, kelebihan, prinsip kerja, dan pertimbangan utama apabila memilih mesin yang sesuai untuk projek pembinaan anda.

Jenis Mesin Pembuat Blok Turap Konkrit Automatik

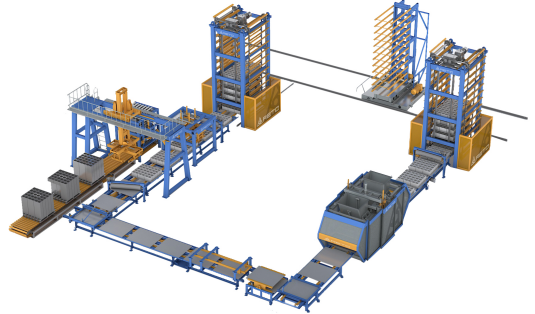

Terdapat dua jenis utama mesin pembuatan blok penurap konkrit automatik:

- Mesin Pembuat Blok Turap Konkrit Automatik Pegun:Mesin ini dipasang di satu lokasi dan sesuai untuk pengeluaran penurap konkrit berskala besar. Mereka menawarkan kadar pengeluaran yang tinggi dan sesuai untuk aplikasi komersial dan perindustrian.

- Mesin Pembuat Blok Turap Konkrit Automatik Mudah Alih:Mesin ini mudah alih dan boleh diangkut dengan mudah ke tapak pembinaan yang berbeza. Ia sesuai untuk projek berskala kecil atau lokasi terpencil di mana mesin pegun tidak boleh dilaksanakan.

Kelebihan Mesin Pembuat Blok Turap Konkrit Automatik

Mesin membuat blok penurap konkrit automatik memberikan banyak kelebihan yang menjadikannya pilihan utama untuk profesional pembinaan:

- Kecekapan:Mesin ini dengan ketara meningkatkan kecekapan pengeluaran dengan mengautomasikan pelbagai proses, seperti mencampurkan, acuan, pemadatan, dan pengawetan.

- Kawalan Kualiti:Automasi memastikan kualiti dan keseragaman yang konsisten dalam pengeluaran penurap konkrit, meminimumkan kecacatan dan pembaziran.

- Pengurangan Buruh:Sifat automatik mesin ini mengurangkan keperluan untuk buruh manual, mengoptimumkan peruntukan sumber dan mengurangkan kos pengeluaran.

- Peningkatan Kapasiti Pengeluaran:Mesin automatik boleh menghasilkan sejumlah besar penurap konkrit dalam jangka masa yang lebih singkat, memenuhi permintaan projek pembinaan berskala besar.

- Ketahanan:Penurap konkrit yang dihasilkan oleh mesin automatik terkenal dengan ketahanan dan jangka hayatnya, menjadikannya sesuai untuk aplikasi tugas berat.

Prinsip Kerja Mesin Pembuat Blok Turap Konkrit Automatik

Prinsip kerja mesin pembuatan blok penurap konkrit automatik melibatkan beberapa langkah utama:

- Percampuran:Bahan mentah, termasuk simen, pasir, agregat, dan air, dicampur dengan sempurna untuk membentuk campuran konkrit seragam.

- pengacuan:Konkrit campuran dituang ke dalam acuan atau rongga mesin pembuat blok. Acuan ini menentukan bentuk dan saiz penurap akhir.

- Memampatkan:Campuran tertakluk kepada tekanan tinggi atau getaran untuk memampatkannya dan mengeluarkan sebarang poket udara, memastikan kekuatan dan ketumpatan penurap.

- Pengawetan:Selepas pemadatan, penurap dibiarkan untuk menyembuhkan untuk tempoh tertentu. Ini membolehkan konkrit mendapat kekuatan dan mengeras.

- Ejection:Setelah proses pengawetan selesai, penurap yang telah siap dikeluarkan secara automatik daripada acuan dan sedia untuk digunakan dalam pembinaan.

Pertimbangan Utama Semasa Memilih Mesin Pembuat Blok Turap Konkrit Automatik

Memilih mesin membuat blok penurap konkrit automatik yang betul adalah penting untuk memastikan prestasi dan kecekapan yang optimum. Berikut adalah beberapa faktor utama yang perlu dipertimbangkan:

- Kapasiti Pengeluaran:Tentukan kapasiti pengeluaran yang diingini berdasarkan keperluan projek anda. Pertimbangkan bilangan penurap yang anda perlukan setiap hari atau jam untuk memenuhi jadual pembinaan anda.

- Saiz dan Bentuk Penurap:Pilih mesin yang boleh menghasilkan saiz dan bentuk penurap khusus yang diperlukan untuk projek anda. Mesin yang berbeza mungkin mempunyai pilihan acuan yang berbeza untuk menampung pelbagai dimensi penurap.

- Sumber kuasa:Pertimbangkan sumber kuasa yang terdapat di tapak pembinaan anda. Mesin membuat blok automatik boleh dikuasakan oleh elektrik, diesel, atau petrol.

- Tahap Automasi:Nilai tahap automasi yang anda perlukan. Sesetengah mesin menawarkan ciri automasi lanjutan, seperti penyusuan bahan automatik, pengawetan, dan lontar blok, yang boleh mengurangkan lagi keperluan buruh.

- Penyelenggaraan dan Alat Ganti:Pertimbangkan ketersediaan perkhidmatan penyelenggaraan dan alat ganti untuk mesin. Penyelenggaraan tetap adalah penting untuk memastikan jangka hayat dan prestasi optimum.

Untuk pelbagai mesin pembuatan blok konkrit automatik, sila hubungi dengan jentera membuat blok pembekal dari China, REIT. Kemudian kami akan memberikan anda maklumat mesin berkualiti dengan harga mesin membuat blok.