Nel campo della costruzione, i blocchi di cemento svolgono un ruolo fondamentale nella creazione di strutture robuste e durevoli. Per garantire la produzione efficiente di questi componenti edilizi essenziali, le macchine per blocchi di cemento sono strumenti indispensabili. Tuttavia, Non tutte le macchine a blocchi di cemento sono create uguali. In questa guida completa, Approfondiamo le caratteristiche delle macchine a blocchi di cemento di qualità, Fornire preziose approfondimenti per aiutarti a prendere una decisione informata quando selezioni la macchina giusta per i tuoi progetti di costruzione.

Caratteristiche essenziali di macchine a blocchi di cemento di qualità:

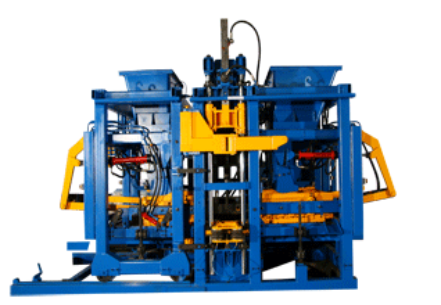

- Costruzione robusta: La durata è fondamentale per a macchina per blocchi di cemento in vendita Ciò sopporterà i rigori del funzionamento continuo. Cerca macchine costruite con materiali di alta qualità, come l'acciaio pesante, per garantire la longevità e l'affidabilità.

- Elevata capacità produttiva: L'efficienza è fondamentale nei progetti di costruzione. Scegli una macchina a blocchi di cemento con un'alta capacità produttiva per soddisfare le esigenze del tuo progetto. Considera fattori come il numero di blocchi prodotti all'ora e la velocità di produzione complessiva.

- Capacità di stampaggio versatili: Diversi progetti di costruzione richiedono dimensioni e forme diverse. Optare per una macchina a blocchi di cemento con capacità di stampaggio versatili, permettendoti di produrre una vasta gamma di tipi di blocchi e dimensioni.

- Operazione automatizzata: L'automazione semplifica il processo di produzione di blocchi, Ridurre i requisiti del lavoro e aumentare la produttività. Cerca macchine con funzionalità automatizzate come l'alimentazione di materiale automatico, Blocca l'espulsione, e impilamento.

- Formazione di blocchi precisi: I blocchi di cemento di qualità richiedono uno stampaggio preciso per garantire l'integrità strutturale. Scegli una macchina che produce blocchi con dimensioni coerenti, superfici lisce, e bordi affilati.

- Durata e longevità: Una macchina a blocchi di cemento è un investimento a lungo termine. Cerca macchine con componenti durevoli, come stampi resistenti all'usura e cuscinetti pesanti, Per garantire una lunga durata di servizio.

- Efficienza energetica: Il consumo di energia è un fattore significativo nei costi di costruzione. Seleziona una macchina a blocchi di cemento che funziona in modo efficiente, consumo meno energia mantenendo l'alta produttività.

- Caratteristiche di sicurezza: La sicurezza dovrebbe essere sempre una priorità assoluta. Scegli una macchina a blocchi di cemento dotato di funzionalità di sicurezza come pulsanti di arresto di emergenza, protezione da sovraccarico, e adeguati meccanismi di protezione.

Considerazioni aggiuntive:

- Reputazione del marchio: Prendi in considerazione la reputazione e la track record del produttore di macchine a blocchi di cemento. I marchi consolidati spesso forniscono prodotti affidabili e un servizio di vendita.

- Servizio dopo la vendita: Il servizio post-vendita è cruciale per mantenere le prestazioni e la longevità della macchina. Cerca produttori che offrono completi dopo la vendita, compresa la disponibilità dei pezzi di ricambio e il supporto tecnico.

- Regolamenti locali: Assicurarsi che la macchina a blocchi di cemento che scegli sia conforme alle normative locali e agli standard per le attrezzature da costruzione.

La selezione della macchina a blocchi di cemento giusto è essenziale per raggiungere l'efficienza, produttività, e qualità nei progetti di costruzione. Considerando le funzionalità discusse in questa guida, Puoi prendere una decisione informata che si allinea ai tuoi requisiti specifici. Investi in una macchina a blocchi di cemento di qualità e getta le basi per sforzi di costruzione di successo.