Scegliere il diritto macchina per la produzione di blocchi di cemento in vendita richiede un'attenta considerazione della capacità produttiva, dimensione e forma del blocco, Qualità del materiale, livello di automazione, Requisiti di potenza, e supporto di manutenzione. Selezionando una macchina adatta e seguendo le pratiche di manutenzione essenziali, Puoi garantire una produzione efficiente e affidabile di blocchi di cemento per i tuoi progetti di costruzione.

Fattori da considerare quando si sceglie una macchina per la produzione di blocchi concreti:

Capacità produttiva: Determina la capacità di output desiderata della macchina in base ai requisiti del progetto. Considera il numero di blocchi necessari per produrre all'ora o al giorno.

Dimensione e forma del blocco: Scegli una macchina in grado di produrre le dimensioni e la forma specifiche dei blocchi necessari. Le dimensioni dei blocchi comuni includono blocchi rettangolari standard, blocchi cavi, e blocchi ad incastro.

Qualità del materiale: Valuta la qualità dei materiali utilizzati nella costruzione della macchina, come la cornice, scatola dello stampo, e sistema idraulico. I materiali durevoli garantiscono la longevità e l'affidabilità.

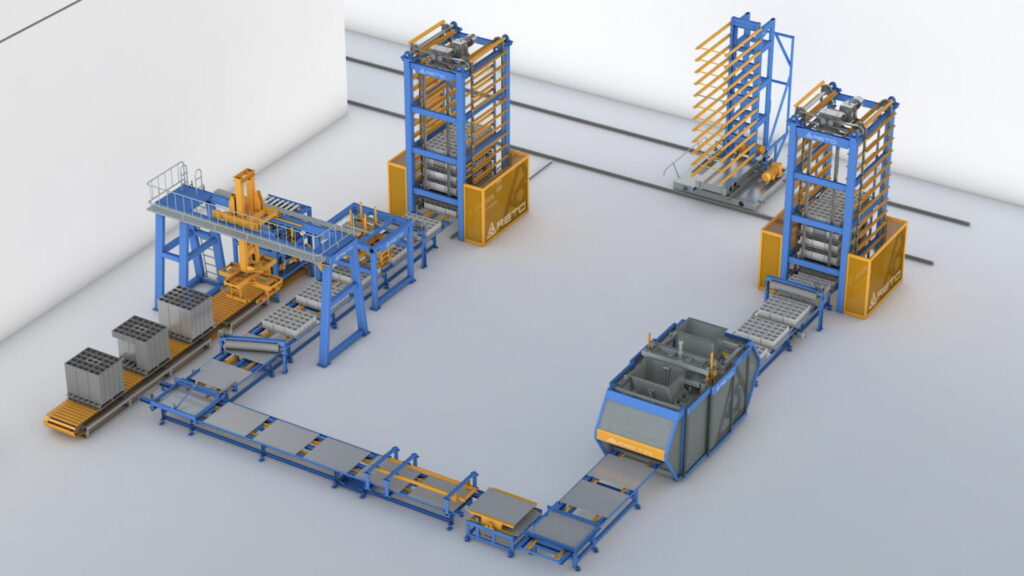

Livello di automazione: Considera il livello di automazione che desideri. Le macchine completamente automatiche richiedono un intervento umano minimo, Mentre le macchine semi-automatiche possono richiedere il caricamento manuale e lo scarico dei materiali.

Requisiti di potenza: Assicurarsi che i requisiti di alimentazione della macchina si allineino con l'alimentazione disponibile. Considera fattori come la tensione, amperaggio, e fase.

Manutenzione e supporto: Scegli una macchina fornita con le linee guida di manutenzione adeguate e il supporto prontamente disponibile da parte del produttore o del fornitore.

Tipi di macchine per la produzione di blocchi di cemento:

Macchine per pressione idraulica: Queste macchine usano la pressione idraulica per comprimere la miscela di cemento negli stampi, produrre blocchi ad alta densità e durevoli.

Macchine da vibrazione: Le macchine per vibrazioni utilizzano la tecnologia di vibrazione per compattare la miscela in cemento, con conseguenti blocchi uniformi e liscio.

Macchine per estrusione: Le macchine per estrusione estrulgono continuamente la miscela di cemento attraverso un dado, Creazione di blocchi lunghi che vengono quindi tagliati in lunghezze desiderate.

Macchine manuali e semiautomatiche: Le macchine manuali richiedono uno sforzo umano significativo, mentre le macchine semi-automatiche offrono un equilibrio tra lavoro manuale e automazione.

Suggerimenti di manutenzione essenziali per macchine per la produzione di blocchi in cemento:

Pulizia regolare: Mantieni pulita la macchina rimuovendo eventuali residui o detriti in cemento dopo ogni utilizzo. Ciò impedisce i blocchi e garantisce un funzionamento regolare.

Lubrificazione: Seguire le linee guida del produttore per lubrificare le parti in movimento per ridurre al minimo l'usura.

Cura della muffa: Ispezionare e pulire regolarmente gli stampi per garantire una corretta formazione di blocchi e prevenire difetti.

Manutenzione del sistema idraulico: Per macchine idrauliche, Controllare il livello e la condizione dell'olio idraulico, e sostituirlo secondo il programma consigliato.

Controlli elettrici: Garantire adeguati collegamenti elettrici e ispezionare il cablaggio per eventuali danni o collegamenti allentati.

Ispezioni regolari: Condurre ispezioni di routine delle condizioni generali della macchina, incluso il controllo di eventuali segni di usura, danno, o disallineamento.