Nel settore edile, efficienza e qualità sono fondamentali. Le macchine a blocchi in cemento svolgono un ruolo vitale nel soddisfare questi requisiti offrendo un metodo affidabile ed efficiente per produrre blocchi di cemento. Queste macchine sono essenziali nel settore delle costruzioni, Fornire le basi necessarie per le strutture robuste. Come addetti ai lavori senior del produttore di macchine a blocchi in cemento, Ti dirò di più di seguito.

Vantaggi delle macchine a blocchi in cemento

Le macchine a blocchi in cemento offrono diversi vantaggi che contribuiscono all'efficienza e alla qualità dei progetti di costruzione. Ecco alcuni vantaggi chiave:

- Produttività incrementata: Le macchine a blocchi in cemento automatizzano il processo di produzione di blocchi, aumento significativo della produttività rispetto ai metodi manuali. Queste macchine possono produrre un gran numero di blocchi in un tempo più breve, consentendo ai progetti di costruzione di progredire in modo più efficiente.

- Qualità costante: Le macchine a blocchi in cemento garantiscono una qualità costante nella produzione di blocchi. Forniscono un controllo preciso sulla miscela, compattazione, e processi di stagionatura, con conseguenti blocchi uniformi con resistenza e dimensioni coerenti. Ciò garantisce l'integrità strutturale e la durata degli edifici costruiti.

- Versatilità: Le macchine a blocchi in cemento possono produrre una varietà di tipi di blocchi, compresi blocchi solidi, blocchi cavi, blocchi ad incastro, e blocchi di pavimentazione. Questa versatilità consente la flessibilità nei progetti di costruzione, Accogliere diversi requisiti di progettazione e funzionali.

- Efficienza dei costi: I blocchi di cemento prodotti dalle macchine a blocchi offrono efficienza dei costi nella costruzione. Questi blocchi richiedono meno mortaio per l'installazione, ridurre i costi del lavoro, e fornire migliori proprietà di isolamento termico. Inoltre, La durata e i bassi requisiti di manutenzione dei blocchi di cemento contribuiscono a risparmi sui costi a lungo termine.

Applicazioni di macchine a blocchi in cemento

Le macchine a blocchi in cemento trovano ampie applicazioni nel settore delle costruzioni. Ecco alcune aree chiave in cui vengono utilizzate queste macchine:

- Edilizia residenziale: I blocchi di cemento sono ampiamente utilizzati nella costruzione residenziale per le pareti dell'edificio, fondazioni, e partizioni. Le macchine a blocchi in cemento consentono una produzione efficiente di questi blocchi, Facilitare la costruzione di case, appartamenti, e altre strutture residenziali.

- Edilizia commerciale e industriale: I blocchi di cemento sono essenziali nella costruzione commerciale e industriale, dove la durata e l'integrità strutturale sono cruciali. Questi blocchi vengono utilizzati per la costruzione di magazzini, fabbriche, uffici, scuole, ospedali, e altri edifici commerciali e industriali. Le macchine a blocchi di cemento assicurano la disponibilità di blocchi di alta qualità per tali progetti.

- Progetti infrastrutturali: Le macchine a blocchi in cemento svolgono un ruolo vitale nei progetti infrastrutturali come le strade, ponti, e muri di sostegno. Queste macchine producono blocchi utilizzati per varie applicazioni, compreso il controllo dell'erosione, stabilizzazione della pendenza, e barriere sonore.

- Spazi paesaggistici e esterni: I blocchi di cemento prodotti dalle macchine a blocchi vengono utilizzati per la creazione di spazi esterni, come i patii, passerelle, vialetti, e pareti del giardino. La versatilità dei progetti a blocchi consente soluzioni di paesaggio creativo in contesti residenziali e commerciali.

Macchina a blocchi in cemento in vendita Con suggerimenti appiccicosi da scegliere

Selezionare la giusta macchina a blocchi in cemento in vendita è fondamentale per garantire prestazioni e produttività ottimali. Considera i seguenti fattori quando si effettua un acquisto:

- Capacità e produzione: Determinare la capacità di produzione richiesta in base alla domanda prevista per blocchi di cemento. Scegli una macchina in grado di soddisfare o superare questa capacità di evitare i colli di bottiglia in produzione.

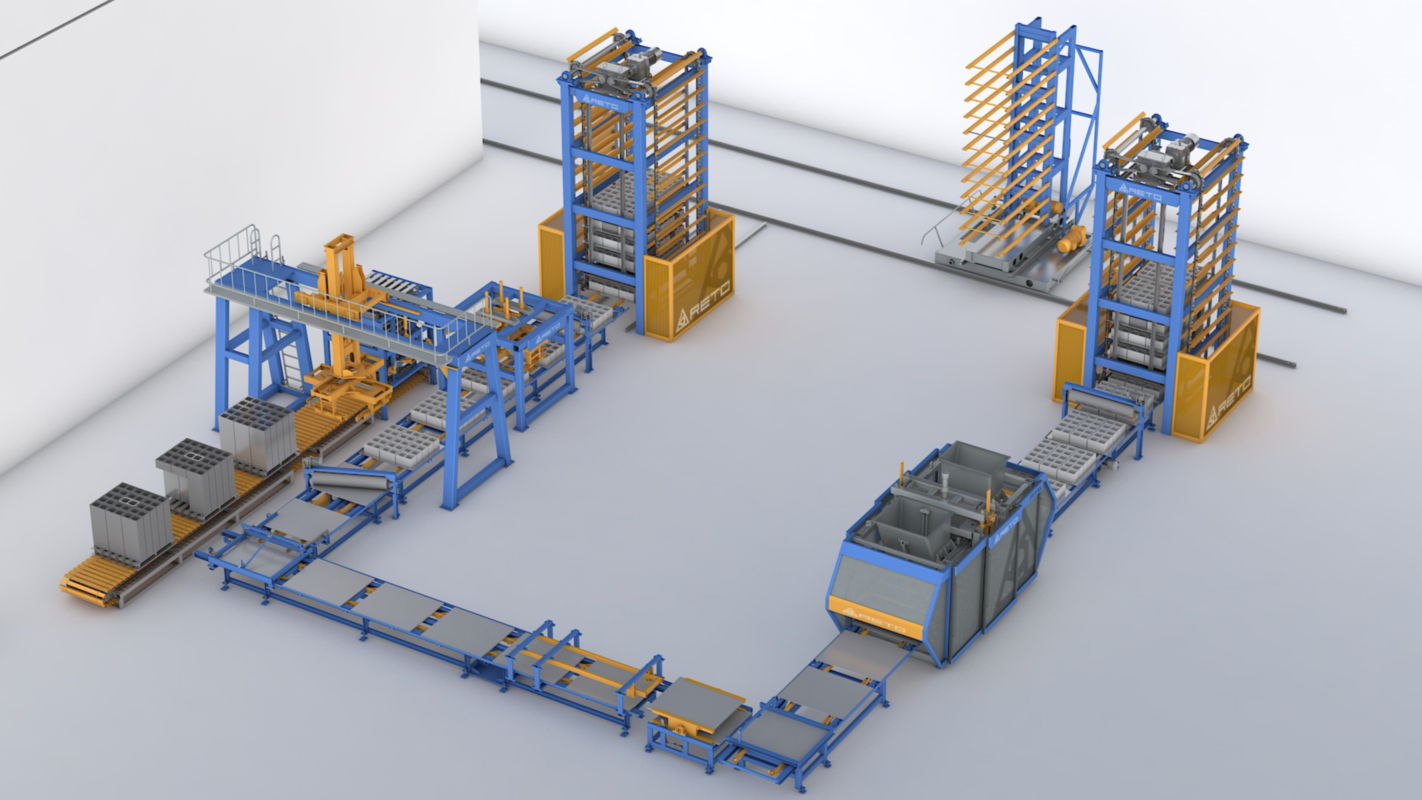

- Automazione e funzionalità: Valuta il livello di automazione e funzionalità offerte dalla macchina. Caratteristiche avanzate, come i controlli computerizzati, sistemi di alimentazione automatica, e intercambiabilità alla muffa, Migliorare la produttività e la facilità di funzionamento.

- Qualità e durata: Assicurarsi che la macchina sia costruita con componenti e materiali di alta qualità per resistere all'ambiente di costruzione impegnativo. Cerca produttori affidabili noti per la produzione di macchine affidabili e durevoli.

- Supporto post-vendita: Considera la disponibilità del supporto post-vendita, compresi i servizi di manutenzione, Disponibilità dei pezzi di ricambio, e assistenza tecnica. Un fornitore affidabile dovrebbe fornire un supporto completo per garantire il funzionamento ininterrotto della macchina.