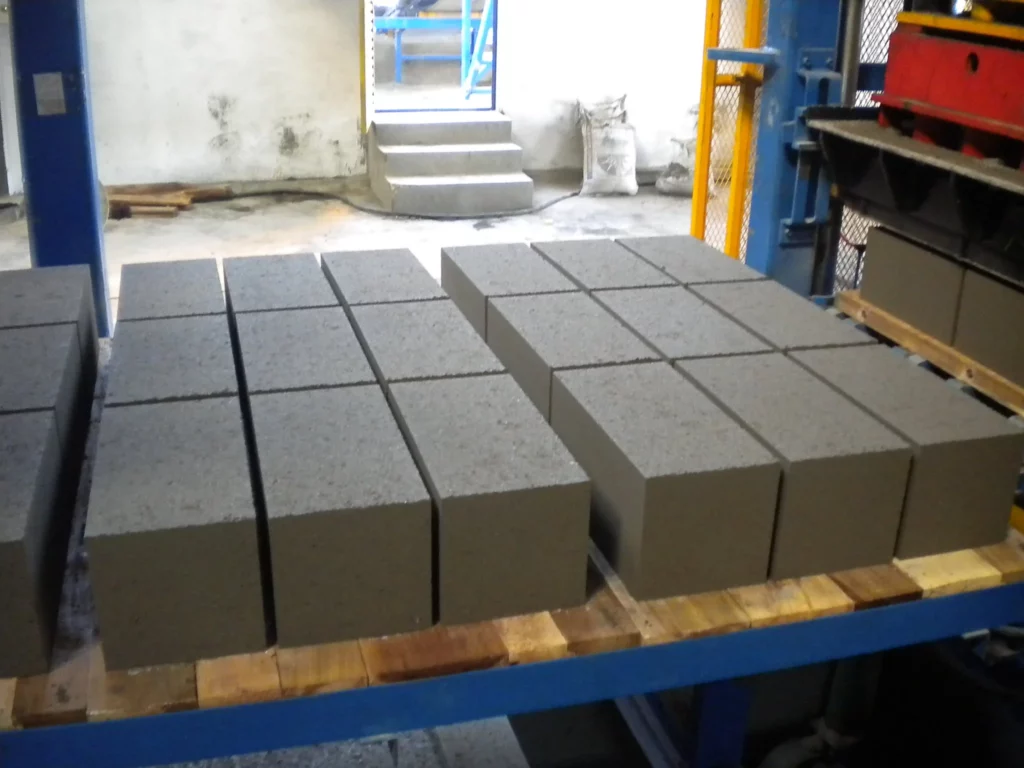

It automatisearjen fan jo operaasjes mei REIT folslein automatyske masine foar it meitsjen fan betonblokken kin de effisjinsje signifikant ferbetterje, ferminderje kosten, en soargje foar konsekwinte kwaliteit. Hjir is in wiidweidige hantlieding om jo te helpen te begjinnen:

1. Begryp de foardielen fan automatisearring:

Foardat dûke yn automatisearring, erkenne de foardielen dy't it bringt. It automatisearjen fan jo bakstienproduksje soarget foar rapper útfier, konsekwinte kwaliteit, en fermindere arbeidskosten. It minimearret minsklike flater en streamlines it hiele produksjeproses.

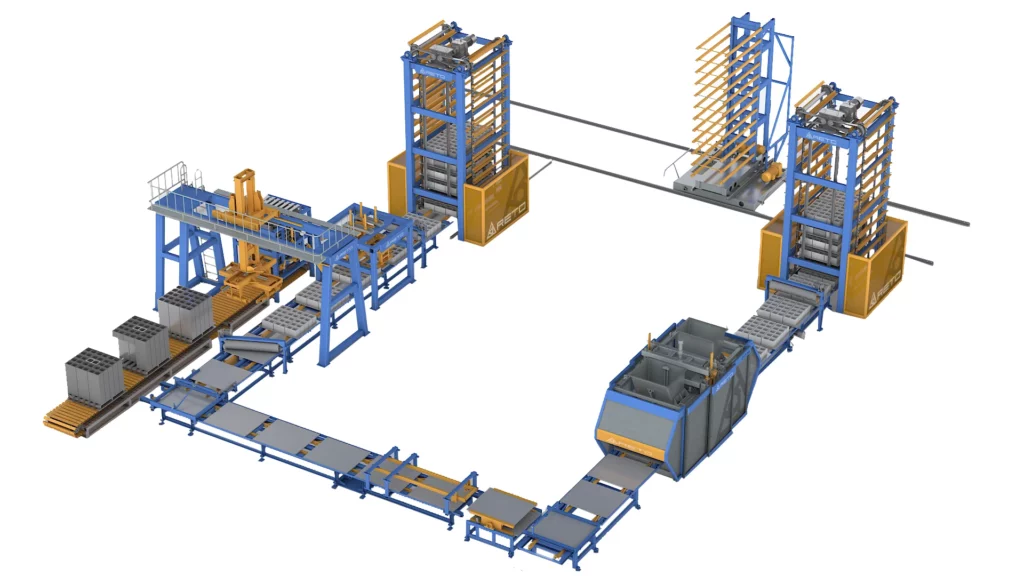

2. Selektearje de juste masine:

Kies de juste REIT automatyske blok making machine ôfstimd op jo produksje behoeften is krúsjaal. Tink oan faktoaren lykas deistige útfierkapasiteit, romte easken, en spesifike funksjes dy't oerienkomme mei jo produksjedoelen. REIT biedt in oanbod fan masines geskikt foar ferskate skalen fan operaasje.

3. Opset en ynstallaasje:

Sadree't jo hawwe selektearre dyn betonblok making machine, soargje foar in goede ynstallaasje. Folgje de rjochtlinen fan 'e fabrikant en lit oplaat professionals de opset behannelje. Goede ynstallaasje is essinsjeel foar optimale prestaasjes en langstme fan 'e apparatuer.

4. Training dyn ploech:

Om de foardielen fan automatisearring te maksimalisearjen, ynvestearje yn training foar jo operators. Fertroud mei de funksjes fan 'e masine, ûnderhâld prosedueres, en techniken foar probleemoplossing. In goed oplaat team soarget foar soepele operaasjes en ferbettert de produktiviteit.

5. Monitor en optimalisearje produksje:

Nei it automatisearjen fan jo produksje, kontrolearje prestaasjemetriken kontinu. Analysearje produksje snelheid, kwaliteitsbeweitsing, en materiaalgebrûk. Brûk dizze gegevens om ynformearre oanpassingen te meitsjen dy't effisjinsje fierder ferbetterje en ôffal ferminderje.

Troch dizze gids te folgjen, jo kinne jo bakstienproduksje mei súkses automatisearje mei REIT folslein automatyske masine foar it meitsjen fan betonblokken, jo operaasjes transformearje en jo bedriuw posysjonearje foar takomstige groei.