Fournisseurs de machines de fabrication de blocs entièrement automatiques

| Nom du produit | machine de fabrication de blocs entièrement automatique |

| Force vibratoire | 80KN |

| Puissance vibratoire | 2X2.5KW |

| Moteur entraîné | 1.5kW |

| Cycle de fonctionnement | 15~30s |

| Vitesse de transport | 0.1—0,17m/s |

Envisagez de contacter REIT pour une compréhension plus approfondie des données des machines de fabrication de blocs entièrement automatiques et des requêtes sur les prix de gros..

Définition de la machine de fabrication de blocs entièrement automatique:

la machine de fabrication de blocs entièrement automatique représente un équipement dédié qui permet la création de blocs de construction en béton, unités de pavage, et une variété d'autres articles en béton préfabriqué. Cette machinerie de pointe rationalise les processus de mélange, façonner, et durcir le béton, résultant en un robuste, efficace, et une production de qualité supérieure qui surpasse les techniques manuelles traditionnelles. En tant que niveau supérieur fournisseurs de machines de fabrication de blocs entièrement automatiques, REIT se positionne à l’avant-garde des avancées du secteur de la construction. Leurs équipements exceptionnels et innovants remodèlent les fondements des méthodologies de construction en Chine et dans le monde., révolutionner la façon dont les produits en béton sont fabriqués.

Comment fonctionne la machine de fabrication de blocs entièrement automatique?

- Chargement de matières premières: la machine de fabrication de blocs entièrement automatique est méticuleusement alimentée avec les ingrédients essentiels – ciment, le sable, gravier, et de l'eau. Cela peut être fait manuellement ou via un système d'alimentation automatisé, assurer des mesures précises et des proportions exactes.

- Mélange: Une fois les matières premières chargées, la machine de fabrication de blocs entièrement automatique utilise ses mécanismes avancés pour les mélanger soigneusement. Utilisation d'un mélange à haute vitesse et haute intensité, ils assurent un mélange de béton homogène et bien incorporé.

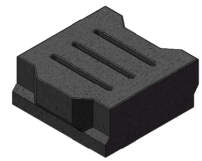

- Moulage: Le béton bien mélangé est soigneusement coulé dans des moules de différentes tailles et formes. la machine de fabrication de blocs entièrement automatique utilise son ingénierie de précision pour appliquer le niveau optimal de compactage et de vibration, éliminer les vides d'air et obtenir des blocs robustes et uniformes.

- Éjection: Une fois que les blocs ont pris forme, la machine de fabrication de blocs entièrement automatique les éjecte efficacement des moules. Ce processus rapide permet une production transparente et des temps d'arrêt minimes.

- Guérison: Les blocs éjectés sont ensuite transférés vers une zone de durcissement désignée, où ils subissent un processus de durcissement contrôlé. Cette étape cruciale favorise l’hydratation et le développement progressif de la force, résultant en des produits finaux robustes et durables.

Les applications de la machine de fabrication de blocs entièrement automatique

- Construction résidentielle: Les machines de fabrication de blocs entièrement automatiques sont indispensables pour la construction résidentielle, fournir les blocs de béton essentiels pour construire des fondations solides, murs robustes, et autres composants structurels dans les maisons et les bâtiments résidentiels.

- Construction commerciale: Dans le domaine de la construction commerciale, La machine de fabrication de blocs entièrement automatique brille en produisant des blocs de béton de haute qualité utilisés dans la construction d'immeubles de bureaux, centres commerciaux, entrepôts, et autres structures commerciales.

- Projets d'infrastructures: la machine de fabrication de blocs entièrement automatique joue un rôle crucial dans les projets d'infrastructure, fourniture de blocs de béton durables pour la construction de ponts, autoroutes, barrages, et d'autres développements d'infrastructures majeurs.

- Aménagement paysager: Pour valoriser les espaces extérieurs, La machine de fabrication de blocs entièrement automatique produit des pavés en béton et des blocs de murs de soutènement largement utilisés dans les projets d'aménagement paysager., y compris la création d'allées, terrasses, et murs de soutènement.

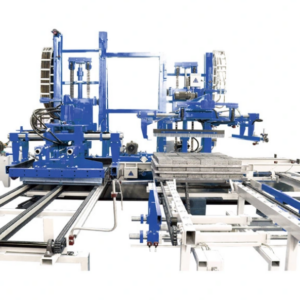

Spectacle d'atelier

Requêtes courantes:

Quel est le prix de vos usines de machines de fabrication de blocs?

Le prix de nos installations de machines de fabrication de blocs de béton est sujet à des variations en fonction de leur degré de sophistication et du rendement souhaité.. Ils peuvent être classés en entièrement automatisés, automatique, et types semi-automatiques. Les prix s'ajustent en fonction du degré d'automatisation et de la production journalière requise. Veuillez nous envoyer un e-mail détaillant vos besoins spécifiques, et nous vous proposerons des options adaptées à votre budget.

- La fourchette de prix des systèmes d'usine de machines à blocs entièrement automatisés se situe entre les États-Unis $550,000 à près de 1 500 000 USD

- Les systèmes d'usine de machines à blocs automatiques sont disponibles aux États-Unis $150,000 à nous $450,000

- Les systèmes d'usine de machines à blocs semi-automatisés peuvent être achetés aux États-Unis $15,000 - NOUS $60,000.

Vos machines peuvent-elles produire d’autres articles que des blocs de béton et des pavés?

- En effet, nos machines sont capables de produire une vaste gamme de produits simplement en modifiant les moules. Certains modèles de machines sont mieux adaptés et plus avantageux pour la fabrication de produits spécifiques.

- Nos machines ont produit une large gamme d'articles en béton. En voici quelques-uns parmi les centaines que nos équipements ont fabriqués.

- Les articles incluent des blocs de construction à noyau creux en béton., Blocs de construction solides, Pavés de rue autobloquants, Blocs de contrôle de l'érosion du béton, Briques pleines et fourrées, Blocs de construction isolés, Blocs de construction sans mortier, Blocs de mur de soutènement, et plus.

Offrez-vous une expédition internationale pour votre équipement?

Absolument. Nous avons une expérience éprouvée en matière d’expédition d’équipements dans le monde entier, y compris des pays et des régions comme les États-Unis, Canada, Russie, Corée, Malaisie, Inde, Moyen-Orient, Afrique du Nord, L'Iran, Chine, etc. En tout, notre équipement de machines à béton a fait son chemin vers plus de 100 pays et régions.