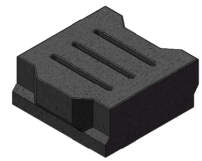

Proveedores de Máquina para fabricar bloques completamente automática

| Nombre del producto | máquina de fabricación de bloques completamente automática |

| Fuerza de vibración | 80KN |

| Poder de vibración | 2X2.5KW |

| motor accionado | 1.5kilovatios |

| Ciclo de operación | 15~30 s |

| Velocidad de transporte | 0.1—0,17 m/s |

Considere comunicarse con REIT para obtener una comprensión más profunda de los datos de las máquinas de fabricación de bloques completamente automáticas y consultas sobre precios mayoristas..

Definición de máquina para fabricar bloques completamente automática:

La máquina para fabricar bloques completamente automática representa un equipo dedicado que permite la creación de bloques de construcción de concreto., unidades de pavimentación, y una variedad de otros elementos prefabricados de hormigón. Esta maquinaria de última generación agiliza los procesos de mezclado, organización, y curar concreto, dando como resultado una robusta, eficiente, y producción de calidad superior que supera las técnicas manuales tradicionales. Como nivel superior proveedores de máquinas para fabricar bloques completamente automáticas, REIT se posiciona a la vanguardia de los avances de la industria de la construcción. Su equipo excepcional e innovador está remodelando las bases de las metodologías de construcción dentro de China y a nivel mundial., revolucionando la forma en que se fabrican los productos de hormigón.

¿Cómo funciona la máquina para fabricar bloques completamente automática??

- Carga de materias primas: La máquina para fabricar bloques completamente automática se alimenta meticulosamente con los ingredientes esenciales. – cemento, arena, grava, y agua. Esto se puede hacer manualmente o mediante un sistema de alimentación automatizado., asegurando mediciones precisas y proporciones exactas.

- Mezclando: Una vez cargadas las materias primas, La máquina para fabricar bloques completamente automática emplea sus mecanismos avanzados para mezclarlos completamente.. Utilizando mezcla de alta velocidad y alta intensidad., aseguran una mezcla de hormigón consistente y bien incorporada.

- Moldura: El hormigón bien mezclado se vierte cuidadosamente en moldes de distintos tamaños y formas.. La máquina para fabricar bloques completamente automática utiliza su ingeniería de precisión para aplicar el nivel óptimo de compactación y vibración., eliminando huecos de aire y logrando bloques resistentes y uniformes.

- Expulsión: Después de que los bloques hayan tomado forma, La máquina para fabricar bloques completamente automática los expulsa eficientemente de los moldes.. Este rápido proceso permite una producción perfecta y un tiempo de inactividad mínimo..

- Curación: Luego, los bloques expulsados se transfieren a un área de curado designada., donde se someten a un proceso de curación controlado. Esta etapa crucial promueve la hidratación y el desarrollo gradual de la fuerza., dando como resultado productos finales robustos y duraderos.

Las aplicaciones de la máquina para fabricar bloques completamente automática.

- Construcción residencial: Las máquinas para fabricar bloques completamente automáticas son indispensables para la construcción residencial., Proporcionar los bloques de hormigón esenciales para construir cimientos sólidos., paredes resistentes, y otros componentes estructurales en viviendas y edificios residenciales..

- Construcción comercial: En el ámbito de la construcción comercial., La máquina para fabricar bloques completamente automática brilla al producir bloques de hormigón de alta calidad utilizados en la construcción de edificios de oficinas., centros comerciales, almacenes, y otras estructuras comerciales.

- Proyectos de infraestructura: La máquina para fabricar bloques completamente automática juega un papel crucial en proyectos de infraestructura., Suministro de bloques de hormigón duraderos para la construcción de puentes., autopistas, represas, y otros importantes desarrollos de infraestructura.

- paisajismo: Para potenciar los espacios exteriores, La máquina para fabricar bloques completamente automática produce adoquines de concreto y bloques para muros de contención que se emplean ampliamente en proyectos de paisajismo., incluyendo la creación de accesos, patios, y muros de contención.

Show de taller

Consultas comunes:

¿Cuál es el precio de sus plantas de máquinas para fabricar bloques??

El precio de nuestras instalaciones de máquinas para fabricar bloques de concreto está sujeto a variabilidad según su grado de sofisticación y el rendimiento deseado.. Se pueden clasificar en totalmente automatizados., automático, y tipos semiautomáticos. Los precios se ajustan según el grado de automatización y la producción diaria requerida.. Envíenos un correo electrónico detallando sus necesidades específicas., y le brindaremos opciones que se adapten a su presupuesto..

- El rango de precios para los sistemas de plantas de máquinas de bloques totalmente automatizadas está entre EE. UU. $550,000 a casi US$1,500,000

- Los sistemas de plantas automáticas de máquinas de bloques están disponibles en EE. UU. $150,000 para nosotros $450,000

- Los sistemas de plantas de máquinas bloqueras semiautomáticas se pueden comprar en EE. UU. $15,000 - A NOSOTROS $60,000.

¿Pueden sus máquinas producir otros artículos además de bloques de hormigón y adoquines??

- En efecto, Nuestras máquinas son capaces de producir una amplia gama de productos simplemente alterando los moldes.. Ciertos modelos de máquinas son más adecuados y más beneficiosos para elaborar productos específicos..

- Nuestras máquinas han producido una amplia gama de artículos de hormigón.. Éstos son algunos de los cientos que nuestro equipo ha fabricado..

- Los artículos incluyen bloques de construcción de hormigón con núcleo hueco., Bloques de construcción sólidos, Adoquines de calles entrelazadas, Bloques de control de erosión de hormigón, Ladrillos macizos y alveolares, Bloques de construcción aislados, Bloques de construcción sin mortero, Bloques de muro de contención, y más.

¿Ofrecen envío internacional para su equipo??

Absolutamente. Tenemos un historial comprobado de envío de equipos a todo el mundo., incluyendo países y regiones como EE.UU., Canada, Rusia, Corea, Malasia, India, Oriente Medio, África del Norte, Irán, Porcelana, etc.. Considerándolo todo, Nuestro equipo de maquinaria de hormigón ha llegado a más de 100 países y regiones.