En la industria de la construcción, La eficiencia y la calidad son primordiales.. Las máquinas para fabricar bloques de hormigón desempeñan un papel fundamental a la hora de cumplir estos requisitos al ofrecer un método fiable y eficiente para producir bloques de hormigón.. Estas máquinas son esenciales en la industria de la construcción, proporcionando la base necesaria para estructuras resistentes. Como experto senior de fabricante de máquinas de bloques de concreto, Te diré más a continuación.

Beneficios de las máquinas de bloques de concreto

Las máquinas de bloques de concreto ofrecen varios beneficios que contribuyen a la eficiencia y la calidad de los proyectos de construcción. Aquí hay algunas ventajas clave:

- Mayor productividad: Las máquinas de bloques de concreto automatizan el proceso de producción de bloques, aumentando significativamente la productividad en comparación con los métodos manuales. Estas máquinas pueden producir una gran cantidad de bloques en un tiempo más corto., permitir que los proyectos de construcción progresen de manera más eficiente.

- Calidad consistente: Las máquinas de bloques de concreto aseguran una calidad constante en la producción de bloques. Proporcionan un control preciso sobre la mezcla, compactación, y procesos de curado, dando como resultado bloques uniformes con resistencia y dimensiones consistentes. Esto garantiza la integridad estructural y la durabilidad de los edificios construidos.

- Versatilidad: Las máquinas de bloques de concreto pueden producir una variedad de tipos de bloques, incluyendo bloques sólidos, bloques huecos, bloques entrelazados, y adoquines. Esta versatilidad permite flexibilidad en proyectos de construcción., acomodar diversos requisitos de diseño y funcionales.

- Eficiencia de rentabilidad: Los bloques de concreto producidos por máquinas de bloques ofrecen una eficiencia de rentabilidad en la construcción. Estos bloques requieren menos mortero para la instalación, reducir los costos laborales, y proporcionar mejores propiedades de aislamiento térmico. Además, Los requisitos de durabilidad y bajo mantenimiento de los bloques de concreto contribuyen a los ahorros de costos a largo plazo.

Aplicaciones de máquinas de bloques de concreto

Las máquinas de bloques de concreto encuentran aplicaciones extensas en la industria de la construcción. Aquí hay algunas áreas clave donde se utilizan estas máquinas:

- Construcción residencial: Los bloques de concreto se utilizan ampliamente en la construcción residencial para las paredes de edificios, cimientos, y particiones. Las máquinas de bloques de concreto permiten la producción eficiente de estos bloques, Facilitar la construcción de casas, apartamentos, y otras estructuras residenciales.

- Construcción Comercial e Industrial: Los bloques de concreto son esenciales en la construcción comercial e industrial, donde la durabilidad y la integridad estructural son cruciales. Estos bloques se utilizan para construir almacenes, fábricas, oficios, escuelas, hospitales, y otros edificios comerciales e industriales. Las máquinas de bloques de concreto aseguran la disponibilidad de bloques de alta calidad para tales proyectos.

- Proyectos de infraestructura: Las máquinas de bloques de concreto juegan un papel vital en los proyectos de infraestructura como las carreteras, puentes, y muros de contención. Estas máquinas producen bloques utilizados para varias aplicaciones., incluyendo control de erosión, estabilización de pendiente, y barreras sonoras.

- Paisajismo y espacios al aire libre: Concrete blocks produced by block machines are used for creating outdoor spaces, such as patios, pasarelas, caminos de entrada, and garden walls. The versatility of block designs allows for creative landscaping solutions in residential and commercial settings.

Máquina de bloques de concreto en venta With Goo Tips To Choose

Selecting the right concrete block machine for sale is crucial to ensure optimal performance and productivity. Consider the following factors when making a purchase:

- Capacity and Output: Determine the required production capacity based on the anticipated demand for concrete blocks. Choose a machine that can meet or exceed this capacity to avoid bottlenecks in production.

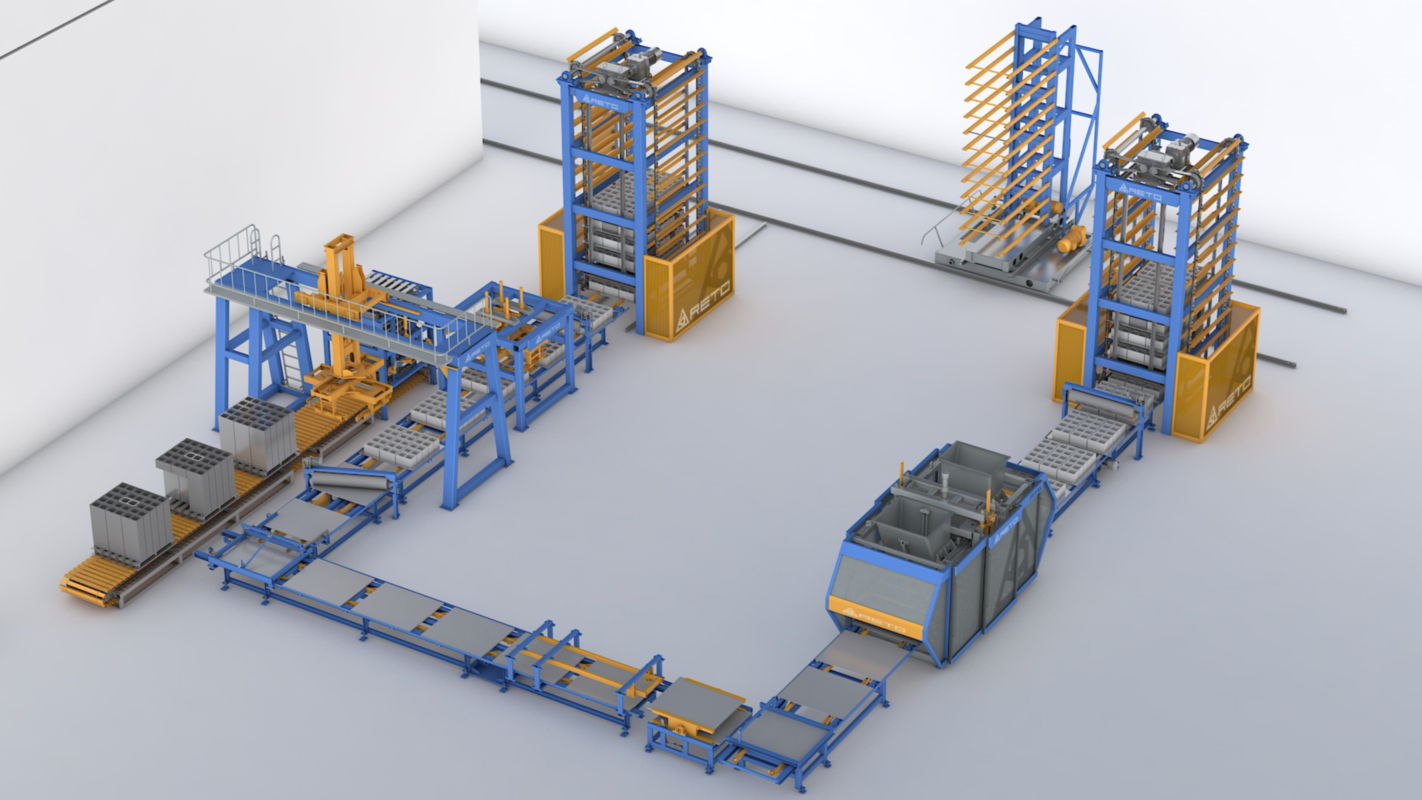

- Automation and Features: Evaluate the level of automation and features offered by the machine. Advanced features, such as computerized controls, automatic feeding systems, e intercambiabilidad de moldes, mejorar la productividad y la facilidad de operación.

- Calidad y durabilidad: Asegúrese de que la máquina esté construida con componentes y materiales de alta calidad para soportar el exigente entorno de construcción.. Busque fabricantes acreditados conocidos por producir máquinas confiables y duraderas..

- Soporte post-venta: Considere la disponibilidad de soporte postventa, incluyendo servicios de mantenimiento, disponibilidad de repuestos, y asistencia técnica. Un proveedor confiable debe brindar soporte integral para garantizar el funcionamiento ininterrumpido de la máquina..