Maschinen zur Herstellung von Kunststeinen spielen eine wichtige Rolle bei der Herstellung hochwertiger architektonischer Kunststeinprodukte, die für Gebäude und Strukturelemente benötigt werden. Diese Maschinen automatisieren den Prozess der Herstellung von Betonsteineinheiten wie Säulen, Ornamentik, facades and more, allowing manufacturers to make consistent, durable products at high volumes.

The Right Architectural Cast Stone Products Machine Can Help:

•Increase productivity – Automated systems mean faster production cycles and higher daily output of cast stone units. This improves manufacturing efficiency.

•Ensure quality – Precise material proportioning, compaction and curing helps deliver cast stone products with uniform dimensions, low absorption and high compressive strength.

•Reduce costs – Weniger Arbeitsaufwand, higher machine uptime and faster changeovers between products can lower the cost per unit produced.

•Improve versatility – Interchangeable molds allow a single machine to produce a variety of architectural cast stone profiles and elements.

Key Factors To Consider When Choosing An Architectural Cast Stone Products Machine Are:

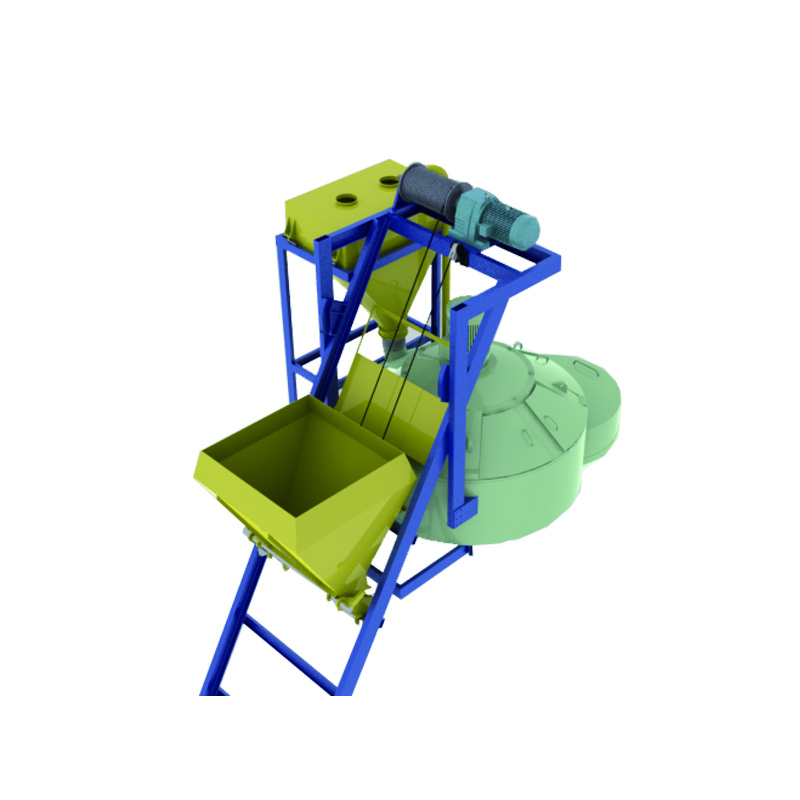

Material Hoppers – Large capacity hoppers ensure consistent material supply to the machine.

Mixing Systems – Precise volumetric or gravity feed mixers are needed for proper mix ratios.

Molding Chambers – Sturdy multi-cavity molds in steel or aluminum compress the mix into the required product shapes.

Verdichtung – Vibrators or rammers compact the mix in the molds for minimum voids.

Curing Systems – Steam curing chambers or ambient curing rooms are required.

Mold Exchange Systems – Quick mold exchange options add flexibility.

Controls – PLC automation ensures repeatability and optimized cycles.

Architectural Cast Stone Manufacturer With Right Machine

With the right machine, architectural cast stone manufacturers can produce high-quality replica stone products for both restoration and new construction projects. Automated production enables consistent results at scale while reducing costs. This allows cast stone fabricators to compete effectively and grow their business.