Whether you’re looking to start a block manufacturing business or expand an existing one, investing in the right block machine is key to high production volumes and quality products. There are several types of block machines to choose from, so researching your options carefully is important.

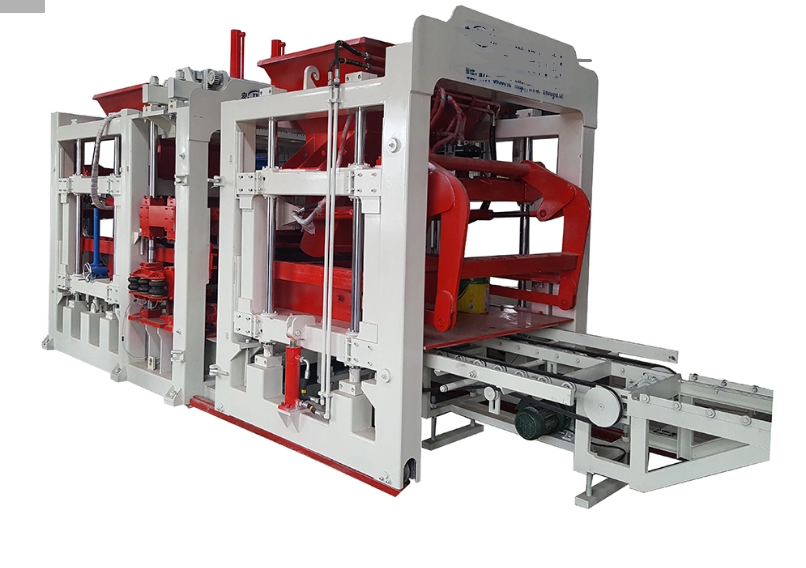

Block Machine For Sales

Consider these factors when buying a block machine:

- How many blocks you need to produce per hour determines the machine size. Larger machines have higher capacities but require more space and laborers.

- Automatic machines offer continuous production while semi-automatic machines require manual feeding and ejection of blocks. Fully automatic tend to have higher throughputs.

- Adjustable molds, hydraulic or pneumatic operation, control panels and maintenance access points vary by brand and model. More advanced features generally cost more.

- High-quality engines, drives and frame materials ensure a long lifespan and reduced downtime. Check manufacturer warranties and reputations.

مصنع آلة تصنيع البلوك

When purchasing from a block machine factory, بحث:

- A reputable company with many years of experience manufacturing block machines.

- A good post-sale service network for quick responses to issues.

- Access to spare parts, maintenance support and training for machine operators.

What Materials Through Block Moulding Machine?

Key considerations for block moulding machine including the material used (metal or alloy molds last longest), mold sizes and shapes offered, temperature control capabilities for curing different types of blocks, and options for automatic mold cleaning and lubrication.