In the realm of construction, cement blocks play a vital role in creating sturdy and durable structures. To ensure the efficient production of these essential building components, cement block machines are indispensable tools. However, not all cement block machines are created equal. In this comprehensive guide, we delve into the features of quality cement block machines, providing valuable insights to help you make an informed decision when selecting the right machine for your construction projects.

Essential Features of Quality Cement Block Machines:

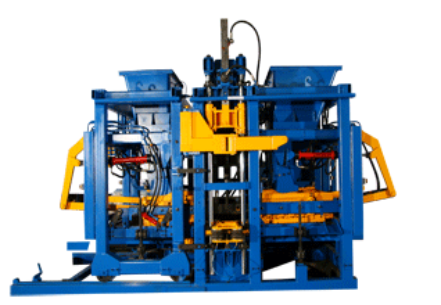

- Robust Construction: Durability is paramount for a cement block machine for sale that will endure the rigors of continuous operation. Look for machines constructed from high-quality materials, such as heavy-duty steel, to ensure longevity and reliability.

- High Production Capacity: Efficiency is key in construction projects. Choose a cement block machine with a high production capacity to meet your project’s demands. Consider factors such as the number of blocks produced per hour and the overall production speed.

- Versatile Molding Capabilities: Different construction projects require different block sizes and shapes. Opt for a cement block machine with versatile molding capabilities, allowing you to produce a wide range of block types and dimensions.

- Automated Operation: Automation streamlines the block-making process, reducing labor requirements and increasing productivity. Look for machines with automated features such as automatic material feeding, block ejection, and stacking.

- Precise Block Formation: Quality cement blocks require precise molding to ensure structural integrity. Choose a machine that produces blocks with consistent dimensions, smooth surfaces, and sharp edges.

- Durability and Longevity: A cement block machine is a long-term investment. Look for machines with durable components, such as wear-resistant molds and heavy-duty bearings, to ensure a long service life.

- Energy Efficiency: Energy consumption is a significant factor in construction costs. Select a cement block machine that operates efficiently, consuming less energy while maintaining high productivity.

- Safety Features: Safety should always be a top priority. Choose a cement block machine equipped with safety features such as emergency stop buttons, overload protection, and proper guarding mechanisms.

Additional Considerations:

- Brand Reputation: Consider the reputation and track record of the cement block machine manufacturer. Established brands often provide reliable products and after sale service.

- After Sale Service: After-sale service is crucial for maintaining the machine’s performance and longevity. Look for manufacturers that offer comprehensive after sale, including spare parts availability and technical support.

- Local Regulations: Ensure that the cement block machine you choose complies with local regulations and standards for construction equipment.

Selecting the right cement block machine is essential for achieving efficiency, productivity, and quality in construction projects. By considering the features discussed in this guide, you can make an informed decision that aligns with your specific requirements. Invest in a quality cement block machine and lay the foundation for successful construction endeavors.