In recent years, the construction industry has witnessed significant advancements in technology that continue to reshape the way buildings and infrastructure are constructed. One such innovation that stands out is the automatic block making machine. This cutting-edge equipment has revolutionized the process of producing concrete blocks, offering remarkable efficiency, precision, and cost-effectiveness.

Automatic Block Making Machines

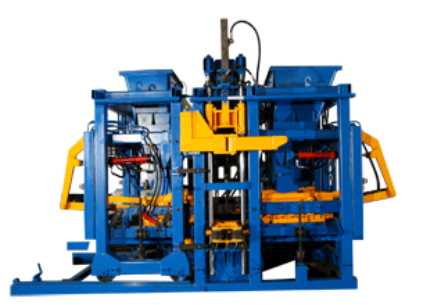

Automatic block making machines are state-of-the-art devices designed to automate the production of concrete blocks, bricks, and other masonry units. These machines employ advanced technology and engineering principles to streamline the manufacturing process, enabling high-speed production with minimal human intervention. The equipment consists of various components, including a concrete mixer, batching system, material feeding mechanism, block mold, hydraulic system, and control panel.

Key Features and Functionality

Automatic block making machines offer a range of impressive features and functionalities that contribute to their efficiency and versatility. Some notable features include:

a) High Production Capacity: These machines can produce a large number of blocks in a relatively short time. With automated material feeding, mixing, molding, and block ejection processes, they can achieve high production rates, enhancing project timelines and productivity.

b) Precise Block Dimension and Quality: Automatic block making machines ensure consistent block dimensions and quality by employing precise molding techniques and uniform compaction. This guarantees uniformity and strength in the produced blocks, meeting industry standards and specifications.

c) Flexibility in Block Designs: These machines allow for the production of various block designs, sizes, and shapes, catering to diverse construction requirements. By simply changing the molds, contractors can create blocks for walls, pavements, fences, and other structural elements, providing design flexibility and customization options.

d) Energy Efficiency: Automatic block making machines are designed to optimize energy consumption. Utilizing efficient motors, hydraulic systems, and automated control mechanisms, they minimize energy waste, resulting in reduced operational costs and environmental impact.

Advantages and Benefits

The utilization of automatic block making machines offers numerous advantages to construction projects of all scales. Some key benefits include:

a) Increased Efficiency and Productivity: By automating the block production process, these machines significantly reduce labor requirements and increase overall project efficiency. The consistent output, high production rates, and reduced manual effort contribute to faster completion of construction projects.

b) Cost-effectiveness: Automatic block making machines help minimize costs associated with labor, material waste, and rework. The optimized production process ensures precise material usage, reducing waste and enhancing cost-effectiveness.

c) Improved Quality Control: The automated nature of these machines ensures consistent block quality, minimizing variations and defects. This results in enhanced structural integrity, durability, and customer satisfaction.

d) Time Savings: With faster production cycles and reduced manual labor, automatic block making machines save considerable time, allowing contractors to meet project deadlines and take on additional projects.

e) Sustainability: These machines promote sustainability by utilizing environmentally friendly materials such as concrete and minimizing waste generation. Furthermore, their energy-efficient design contributes to reduced carbon footprint and resource conservation.

Applications and Future Prospects

Automatic block making machines find application in a wide range of construction projects, including residential, commercial, and infrastructure developments. They are used for manufacturing blocks used in walls, foundations, pavements, retaining walls, landscaping, and more. As the construction industry continues to evolve, the demand for such machines is expected to grow exponentially.

Looking ahead, the future prospects for automatic block making machines are promising. Advancements in technology, such as the integration of artificial intelligence, IoT, and automation, are likely to further enhance their capabilities. Improved control systems, remote monitoring, and predictive maintenance will optimize machine performance, ensuring continuous operation and minimal downtime.